or the last decade, so much buzz about cutting metal has tended to revolve around fiber lasers. But according to MultiCam Inc.’s fabrication product manager, Rashad Galloway, some manufacturers have begun to sing a different tune that sounds oddly reminiscent of Elvis Presley’s hit, “Can’t Help Falling In Love.”

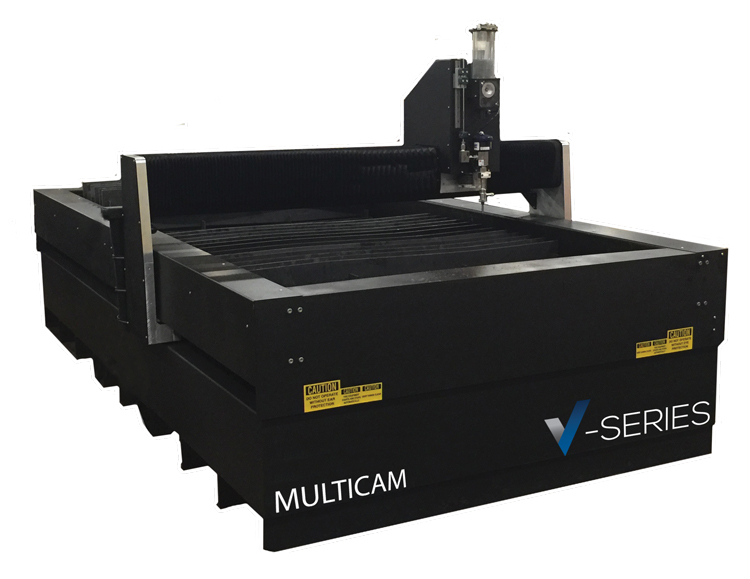

MultiCam demonstrated its V-Series CNC waterjet technology during a 2019 trade show, cutting carbon and stainless steels, titanium and Inconel. “When people saw the value adds they could realize with the final product, they fell in love with the waterjet all over again,” says Galloway.

A KMT Tri-Line pump creates up to 55,000 psi cutting pressure. The low-maintenance machine can be equipped with an optional closed water filtration system, abrasive removal system or intensifier available in 30 horsepower to 200 horsepower.

MultiCam’s equipment developments and interaction with a diverse group of industries have helped it collect data that provides a more precise analysis about material requirements.

“We try to ask customers the right questions such as the type of material they plan to cut, how the part needs to perform and what kind of environment it will be exposed to,” Galloway says. “We know how machines affect material. Manufacturers also need to think about what the cut edge of a part is doing and how it will attach.”

“A business owner wants to know what it will cost to produce the parts they need and what their net gain will be,” notes Galloway. “If you stack a waterjet next to a fiber laser, the fiber is cheaper to run. But what you have to do with the part after you cut it is what matters.”

“We work with a lot of small to medium-sized companies that have a lot riding on capital equipment decisions they hope will produce dividends in terms of business growth,” Galloway says. “At MultiCam we’re about helping customers grow.”

When it comes to manufacturing, time may be money but so is quality.

When it comes to manufacturing, time may be money but so is quality.

Galloway, who began his career with the CNC cutting solutions supplier as a technician in 2013, says he took a “shine to waterjet machines and wanted to learn everything about them” so that he could leverage his knowledge to help manufacturers solve production problems. But he admits to an altruistic motive as well.

“I’m very passionate about fabrication machines,” he says. “My superhero was my grandfather, Thomas Galloway Sr. He was a construction worker who poured the concrete and built the foundations of some of the roads we now drive across. I’m trying to carry that legacy forward through cutting machines.”

The parts that MutiCam waterjets cut and the service and support the company provides “all go into the creation of products that will be used for decades into the future. When it comes to manufacturing, time may be money but so is quality.”

multicam.com.