fabricating & forming technologies

Using an effective DFM strategy can not only improve your current production output but also set you up for a successful growth path in the future.

Using an effective DFM strategy can not only improve your current production output but also set you up for a successful growth path in the future.

Using an effective DFM strategy can not only improve your current production output but also set you up for a successful growth path in the future.

Using an effective DFM strategy can not only improve your current production output but also set you up for a successful growth path in the future.

Features

/customfabricator

/handling

/sawing

From the Editor

he global Industry 4.0 market was estimated at $70 billion in 2019 and is expected to reach $210 billion by 2026, according to a Facts and Factors research report.

The ability to point and click in order to inspect parts, reverse engineer out-of-production parts, and collect data for assembly guidance and best fit analysis is increasingly valuable to shops in search of ways to gain an edge within the industry. Software can make current processes run smoother while leaving the possibility to grow and evolve as customer demand changes.

s we begin the process of recovering from the pandemic, a key component for domestic manufacturing is our ability to embrace and harness the power of the Industrial Internet of Things (IIoT) and integrated systems. Although the terms are familiar, I see too much misinformation that overcomplicates these ideas and their implementation.

Digital Loop

Digital Loop

Digital Loop

n today’s integrated shop floor environment, the lines between dedicated fabrication shops versus machine shops have become blurred. Customer demand for higher value from supply chain partners has prompted companies to expand their scope of services. There is also a greater emphasis on shortening overall manufacturing processes for parts and time to market.

A digital thread connects the development and management of a product’s entire life cycle into a single database. More customers are demanding Industry 4.0 levels of digital documentation across finished assemblies and parts, whether fabricated or machined, because they can. Metrology software and measurement devices have evolved and adapted to the point where 100 percent inspection is now routine. Today’s fabricators can meet Industry 4.0 expectations by implementing a digital model-based metrology strategy.

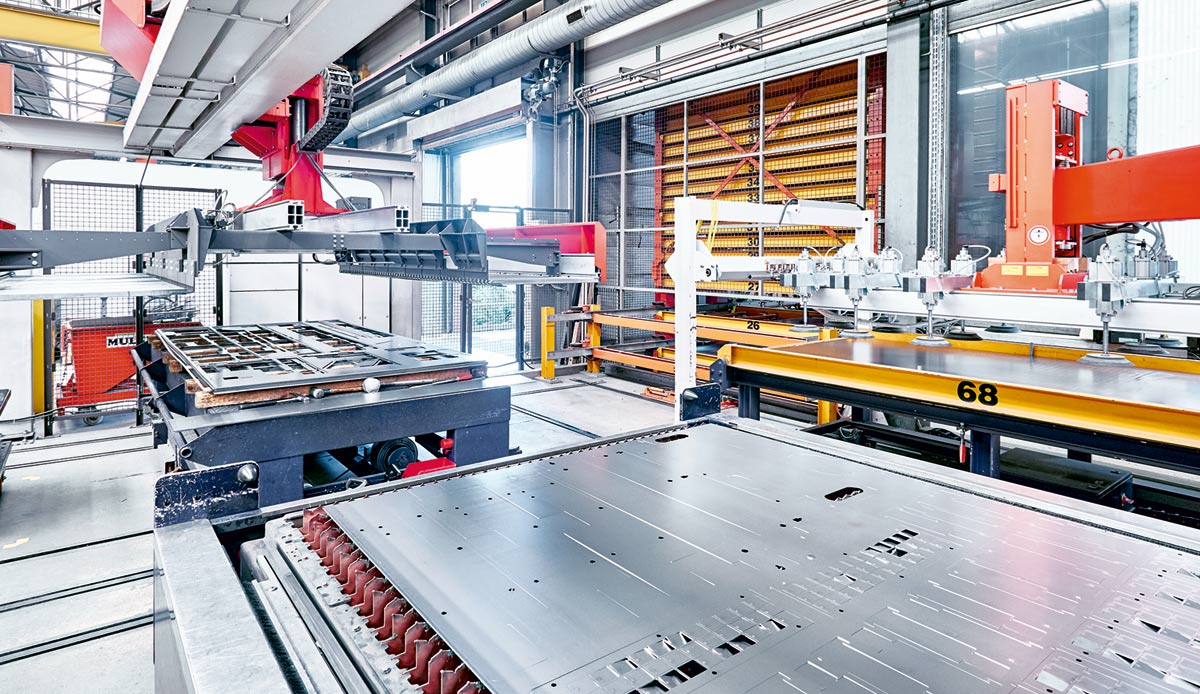

The Virtual Trade Show, Go to

ammons Metal & Manufacturing Co. Inc. is no stranger to growth. The small metal parts and fabrication shop opened its doors in 1968 and has since maintained an upward trajectory. In 1998, the Indianapolis-based company changed hands. Today, Gammons, helmed by owner Dave Sutton, is one of the largest independent metal fabrication companies in the Midwest. The 70,000-sq.-ft. facility can saw, shear, punch, tap, bend, pierce and notch carbon steel, cold rolled, hot rolled pickled and oiled, galvanized, aluminum, stainless, brass and copper. Its skilled personnel can take parts from prototype to production runs, subassemblies, inspection and shipping. Seamless processing is a hallmark of Gammons. A bottleneck in its cutting operations prompted the manufacturer to look at fiber laser technology that could handle larger volumes.

Rolleri analyzed parts and press brake capacity to design/build tooling that could withstand tough materials.

he W. L. French Excavating Corp. is used to pushing obstacles out of the way. The family-owned business based in North Billerica, Massachusetts, provides a wide range of construction services from mass excavation and soil management to site development, transportation, disposal and snow services. Its motto “We move Boston,” is fitting for a company that moves millions of cubic yards of earth annually, prizes its employees and is deeply embedded in its community. W. L. French needed an equally tough tooling solution to bend parts from Hardox 450 steel up to .50-in. thick using a 325-ton press brake.

Formdrilling solves the problem of joining thin-walled material.

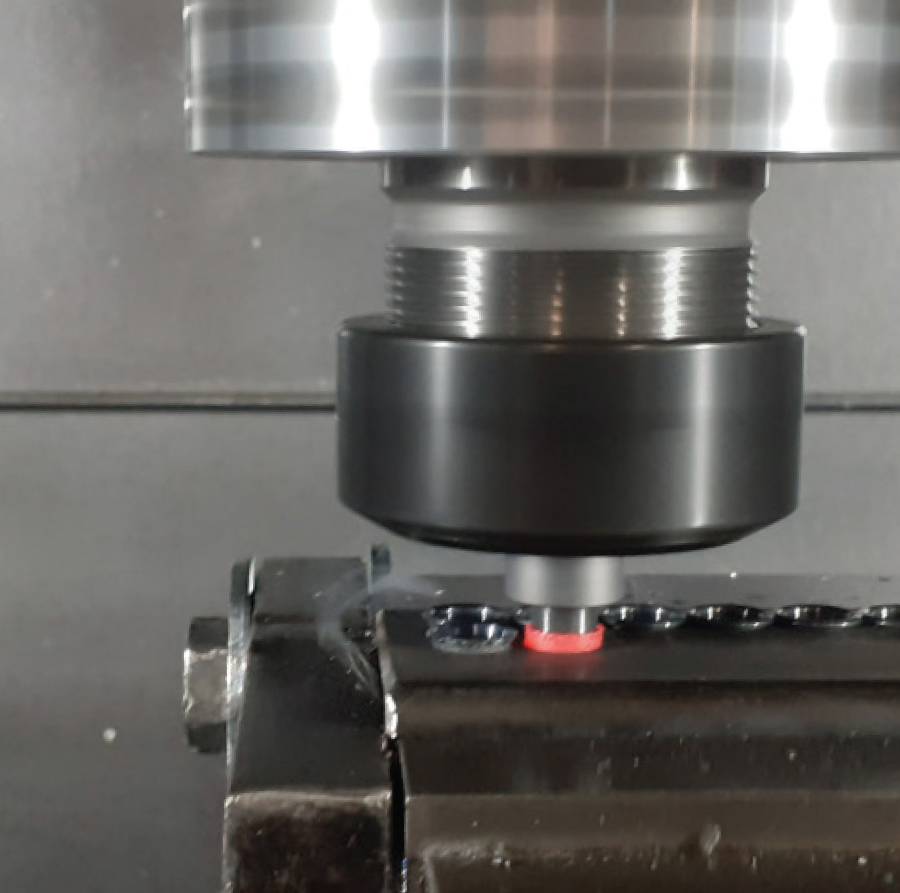

art failure can be a public relations nightmare for manufacturers. It’s a complaint that Todd Bieri, operations manager for Formdrill-USA Inc. hears on a fairly regular basis. “Prior to coming to us, customers have talked about various product failures as a result of using inserts or weld nuts and how that has created a negative image issue for them that they are anxious to reverse,” he says.

utting large-diameter pipe can be cumbersome and time consuming when done manually. After Piping Systems Inc. completed the largest project in its history—a 375,000 linear ft. project with diameters up to 72 in. and wall thicknesses up to 1.5 in.—the fabricator realized its current equipment conveyor system wouldn’t keep up in the long-term. “The equipment’s conveyor we had at the time was only rated for a maximum 500 lbs. per ft. There was no way we could run heavy-wall, large-diameter pipe,” says Tony Kent, vice president, Piping Systems.

conomic activity in the manufacturing sector is growing. In January, manufacturing PMI registered at 58.7 percent. According to the Manufacturing ISM Report on Business, “this figure indicates expansion in the overall economy for the eighth month in a row after contraction in March, April and May 2020.”

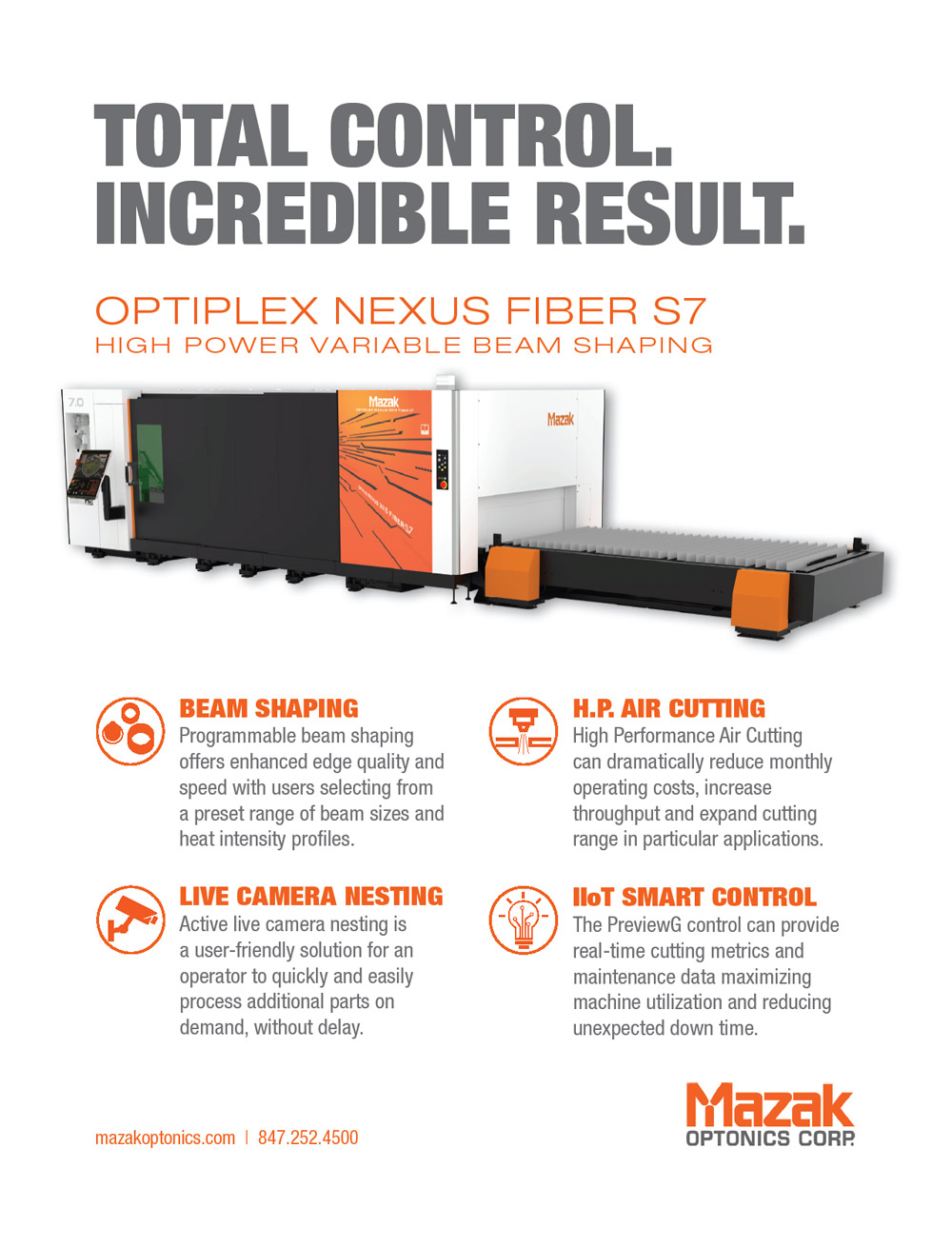

Businesses like Heat and Control Inc. design specialized machinery for the food industry. “We needed a new laser to meet demand while ensuring high-quality finishing so our customers won’t hurt themselves,” says Jessie Castillo, director of manufacturing.

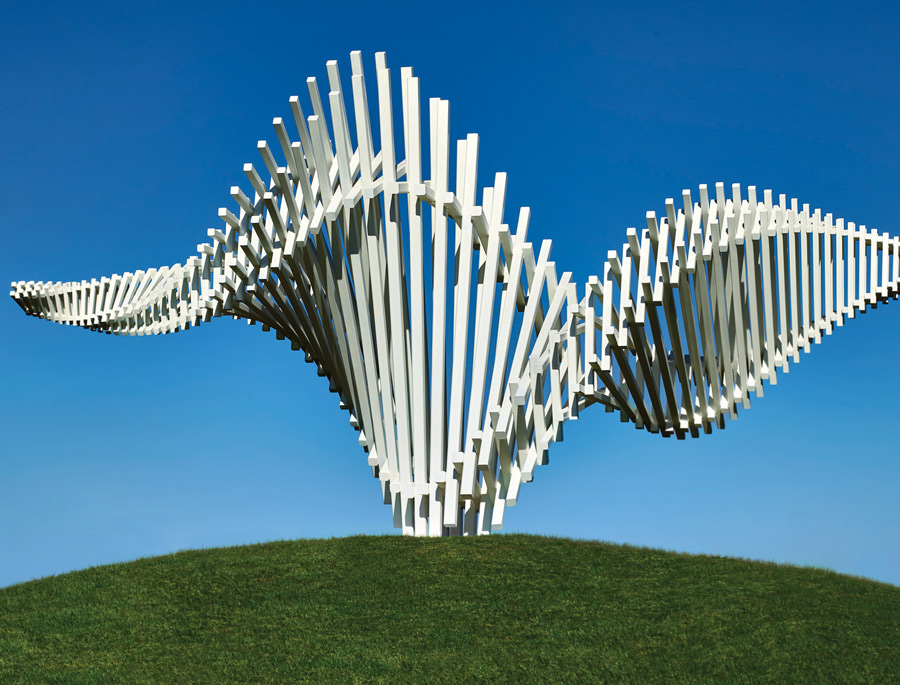

While Breckenridge, Colorado’s December 2020 Ullr Fest was cancelled due to COVID-19, a collaboration between Breckenridge Grand Vacations and Scottish sculptor Andy Scott gave hope that the fabled Norse god of snow will nevertheless provide the area with a frozen bounty. A 25-ft.-tall, 1-ton sculpture of Ullr was assembled and erected at the base of Peak 8 at the Breckenridge Ski Resort November 11, 2020, a few days before the opening of ski season. Scott constructed a wire frame from his concept sketch and covered it with 1-in. pieces of steel welded together to contour the shape. Scott, who told the Summit Daily newspaper he “sees little segments of steel in his sleep,” said his approach of using thousands of tiny pieces of steel came about slowly while he evolved his style. He credits taking some of his inspiration from American painter Chuck Close, who creates portraits by combining hundreds of smaller painted squares. Locals are looking forward to the 2021 Ullr Fest celebration in hopes of another powder-filled ski season.

View Index

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matt LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.