ach time you step onto an elevator or board a bus, there’s a level of trust the rider imparts to those who designed and built each mode of movement.

In Syracuse, New York, Elevator Interiors Inc.’s owner, Joe Piepho, found his operations were hindered by other people’s schedules. Rather than farm out cutting jobs, Piepho began to hunt for equipment that would give the elevator parts manufacturer the ability to cut components efficiently and cleanly in house.

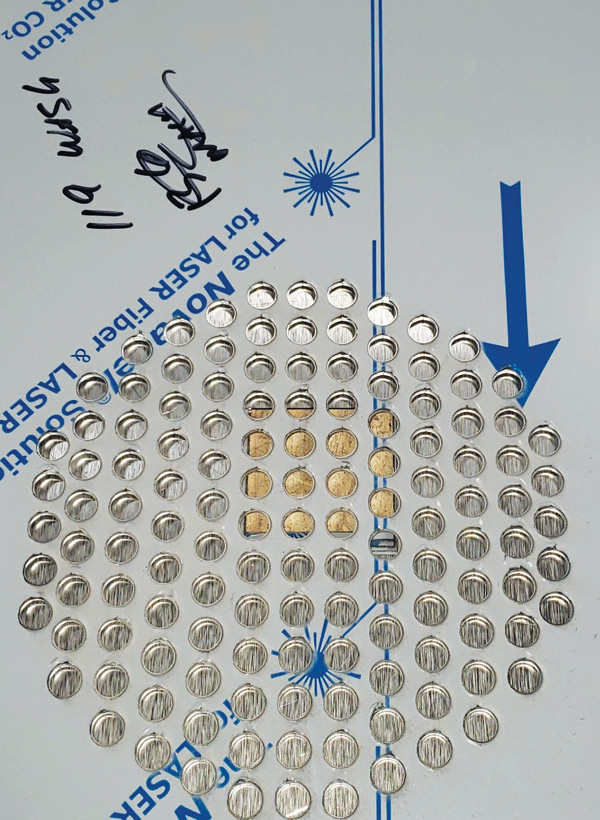

“When we first started working with steel sheet metal, we used a punch and shear and it was incredibly time consuming. We tried plasma and, while that could cut any shape, it wasn’t laser quality,” Piepho says. Elevator Interiors purchased a Laguna Smartshop IPC 5-ft. by 10-ft. fiber laser with 1,000 watt IPG power supply.

Across the country in Riverside, California, Grech Motors fabricates an average of 12 luxury shuttle buses per week, with much of the manufacturing completed in a plant based in Mexicali, Mexico. “We needed a better way to cut tubing,” recalls Carter Read, manufacturing engineer of production and engineering at Grech Motors. “At my old job, we used a Laguna machine and I was brought into Grech to help speed processes along, and to automate [operations].”

Grech Motors purchases the bus chassis and then cuts holes and cuts through the steel frames. “I noticed that our workers had to take tubing and cut it at a 7-degree angle, and after each cut of a 2-ft. by 4-ft. tube, 86 in. long, we had to turn it to the opposite side 7 degrees and cut it again—it was a total of four holes and each time we had to set it up and rotate it again to cut it,” Read says.

We used to just make parts; now we engineer parts.

We used to just make parts; now we engineer parts.

In addition to the sheet cutting capabilities of the FC, the DLP has a tube-cutting system capable of processing square or round tubes up to 19 ft. long with a diameter of 8 in. Both the FC and DLP machines are PC-based and designed to be scalable and user friendly. Common file types, including CAD, STL, DXF, AI and EPS files can be dropped in and the patterns can be cut almost immediately. Nesting software, including lead-in and lead-out adjustability, report generation and edge detection are built into the fiber laser’s controls.

Grech Motors was able to integrate its DLP system in days. “They were running at full production levels once the installation was signed off,” Alvarez says. “Before purchasing the DLP, Read had no choice but to outsource this work because the cost to manually produce these parts could not be justified.”

After installing the machine, Piepho says his team understood quickly that they did not have to adhere to simply designed parts. “We realized that we can do flanges and things we used to have to stud weld or glue,” he says. “By eliminating hardware, there are a lot less parts. Now we don’t have to stud weld to attach angles. Instead we bend those flanges in and can make a much cleaner, more professional part.

“We used to just make parts; now we engineer parts,” Piepho says.