- HYDRAULIC IRONWORKERS

- CIRCULAR COLD SAWS

- TUBE & PIPE NOTCHERS

- MEASURING DEVICES

Features

/aluminum

/welding

/software

Learn more

@AdvSciNews

From the

Senior Editor

Sky Bound

saw my first flying car in 1962 when The Jetsons hit broadcast television. I was four years old and there were just three networks and 51 shows. Our “tube,” as my Dad called it, was black and white but it didn’t diminish my fascination with the Jetson family’s daily life—which included videophones, conveyor belt sidewalks, robot servants and the FX-Atmos. The flying car sported a glass bubble canopy, dashboard radar screen and tail fins and folded up into a briefcase light enough for George Jetson to carry into his office.

In 1966, I went to outer space with the crew of the starship Enterprise. Star Trek, with its ability to cross galaxies at warp drive and beam personnel to different locations via transporters, is still considered one of the most influential science fiction series in TV history. In 1977, a year after I graduated high school, Star Wars hit the big screen. Cloud cars, air speeders, light sabers and the Force, the source of a Jedi’s power, took my imagination in a different direction.

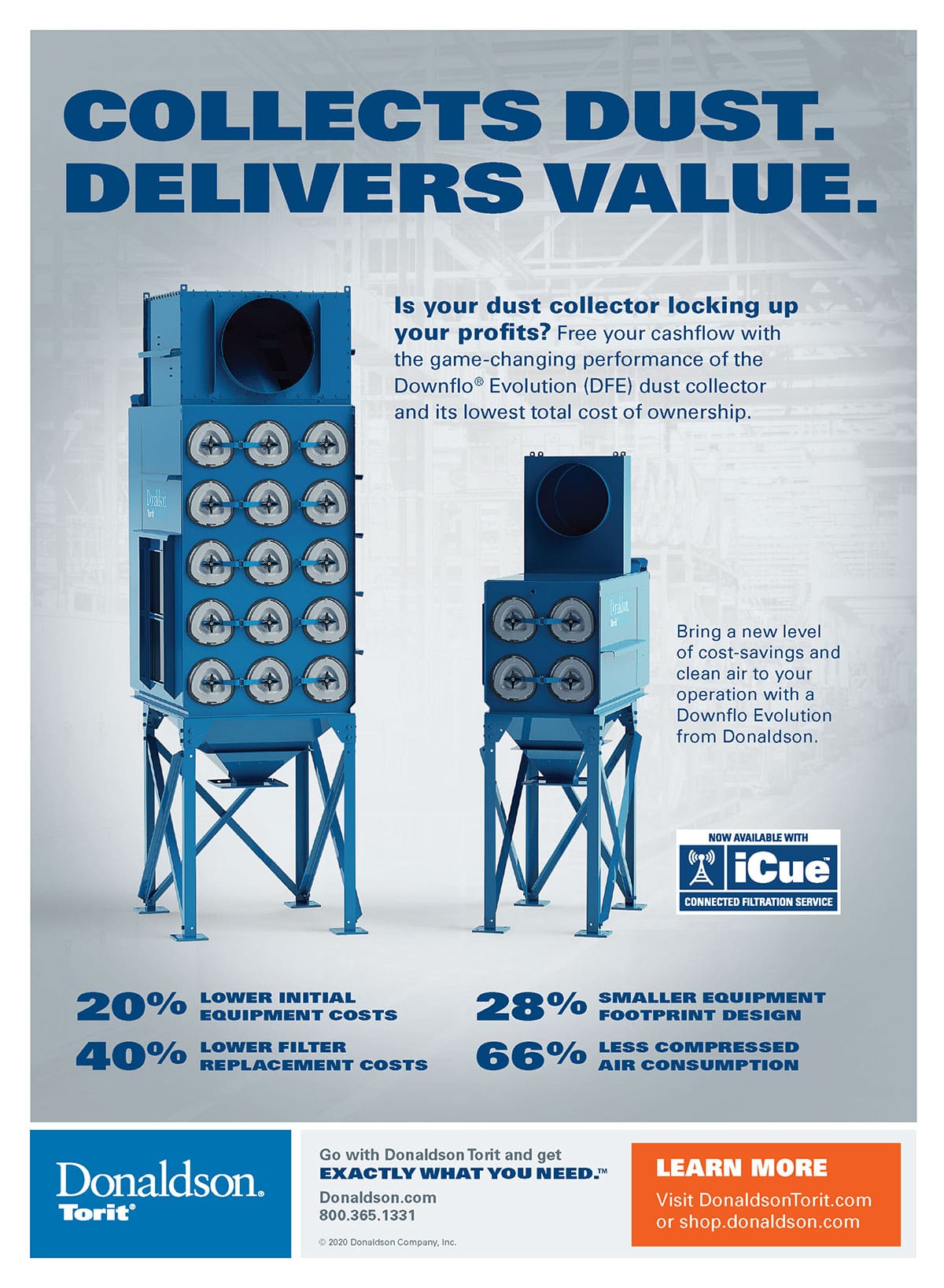

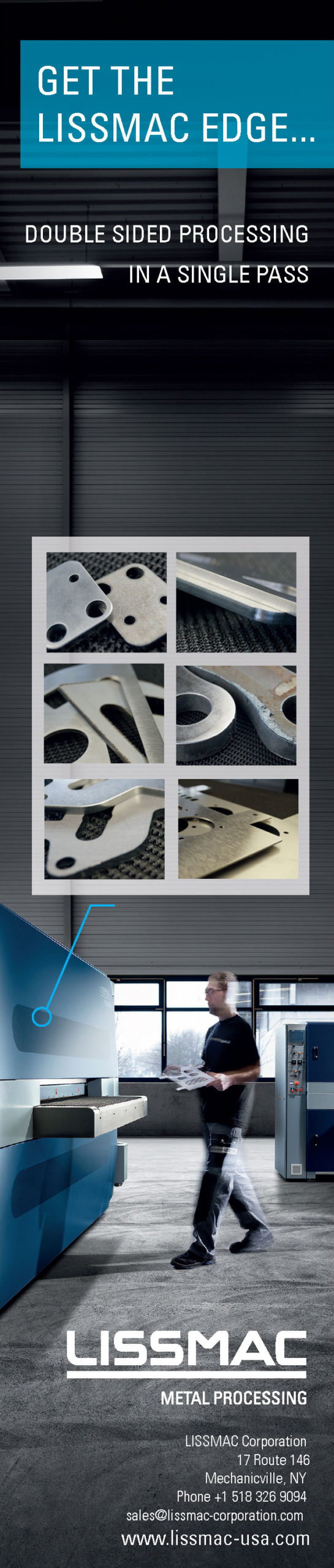

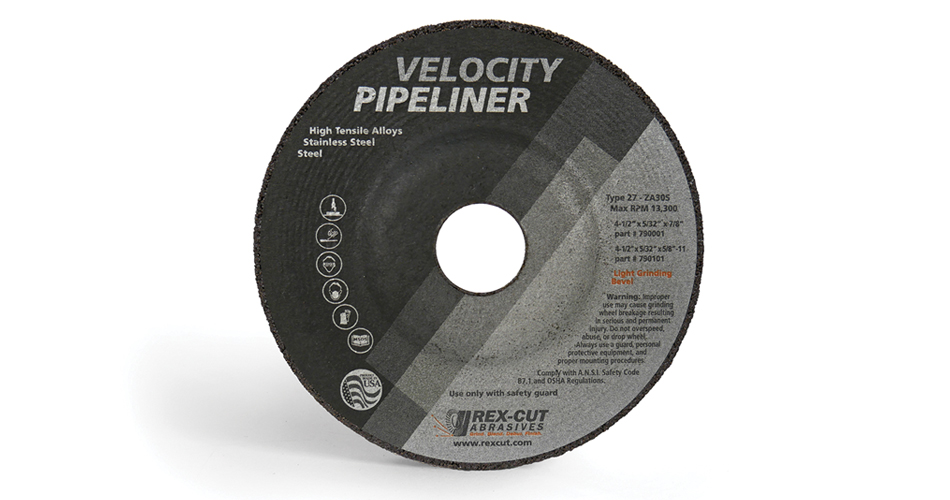

n today’s metalworking and steel fabrication markets, companies must use efficient manufacturing technologies in order to drive down costs and improve productivity. Achieving a competitive advantage amid domestic and international challenges is critical. Manufacturers continue to demand higher quality and craftsmanship from discretionary technical/consumable products and, at the same time, seek lower pricing.

However, when faced with the challenge of correctly identifying improvement initiatives, and/or bottlenecks in an operation, companies must often examine the effectiveness of their skilled workers. This poses the question of how to improve current manufacturing methods and measure processes when productivity is still largely influenced by operators.

Kwik Mark Inc., McHenry, Illinois, 815/363-8268, www.kwikmark.com.

Rex-Cut Abrasives, Fall River, Massachusetts, 800/225-8182, www.rexcut.com.

Through the partnership with Uber, we will harness Hyundai’s businesses and technologies to deliver true freedom of mobility.

Through the partnership with Uber, we will harness Hyundai’s businesses and technologies to deliver true freedom of mobility.

long time ago in a galaxy far, far away,” there were airspeeders. The repulsorlift vehicles—featured in the iconic Star Wars franchise created by George Lucas—used skylanes to move in and out of dense traffic and maneuver between towering buildings on urban planets like Coruscant.

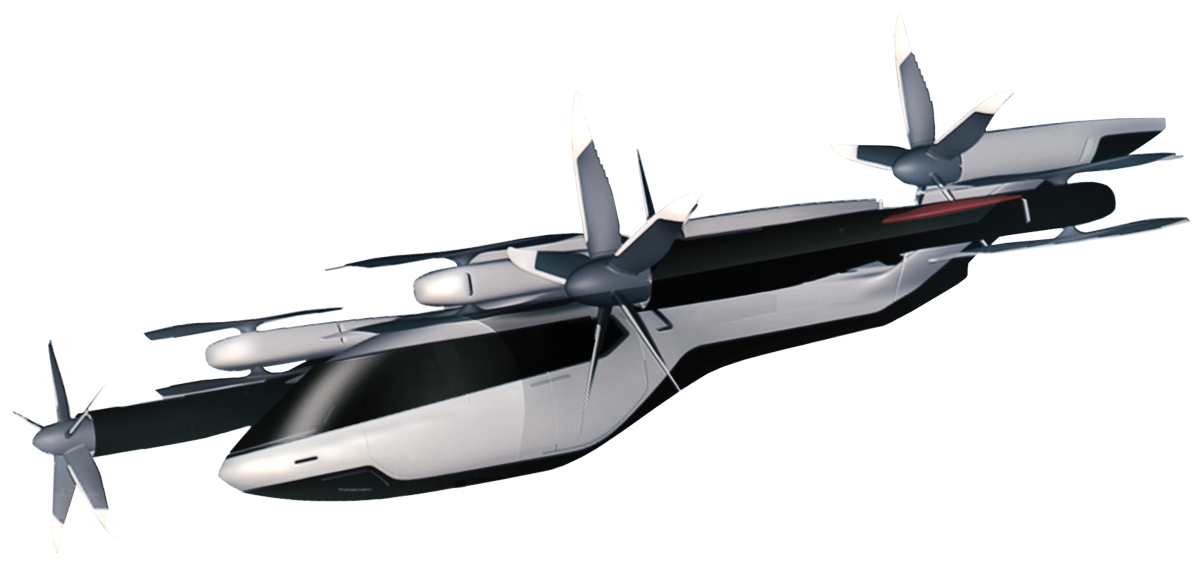

The idea of people traveling highways in the sky is no longer fodder for science fiction and fantasy. On Jan. 6, 2020 Uber and Hyundai Motor Co. announced a new partnership to develop Uber air taxis for a future aerial ride share network at the Consumer Electronics Show (CES) 2020 in Las Vegas. As part of the media event, Hyundai unveiled its S-A1 prototype. The automaker will produce and deploy the all-electric personal air vehicles (PAV), and Uber will provide airspace support services, connections to ground transportation and a ridesharing app called uberAIR.

long time ago in a galaxy far, far away,” there were airspeeders. The repulsorlift vehicles—featured in the iconic Star Wars franchise created by George Lucas—used skylanes to move in and out of dense traffic and maneuver between towering buildings on urban planets like Coruscant.

The idea of people traveling highways in the sky is no longer fodder for science fiction and fantasy. On Jan. 6, 2020 Uber and Hyundai Motor Co. announced a new partnership to develop Uber air taxis for a future aerial ride share network at the Consumer Electronics Show (CES) 2020 in Las Vegas. As part of the media event, Hyundai unveiled its S-A1 prototype. The automaker will produce and deploy the all-electric personal air vehicles (PAV), and Uber will provide airspace support services, connections to ground transportation and a ridesharing app called uberAIR.

ach time you step onto an elevator or board a bus, there’s a level of trust the rider imparts to those who designed and built each mode of movement.

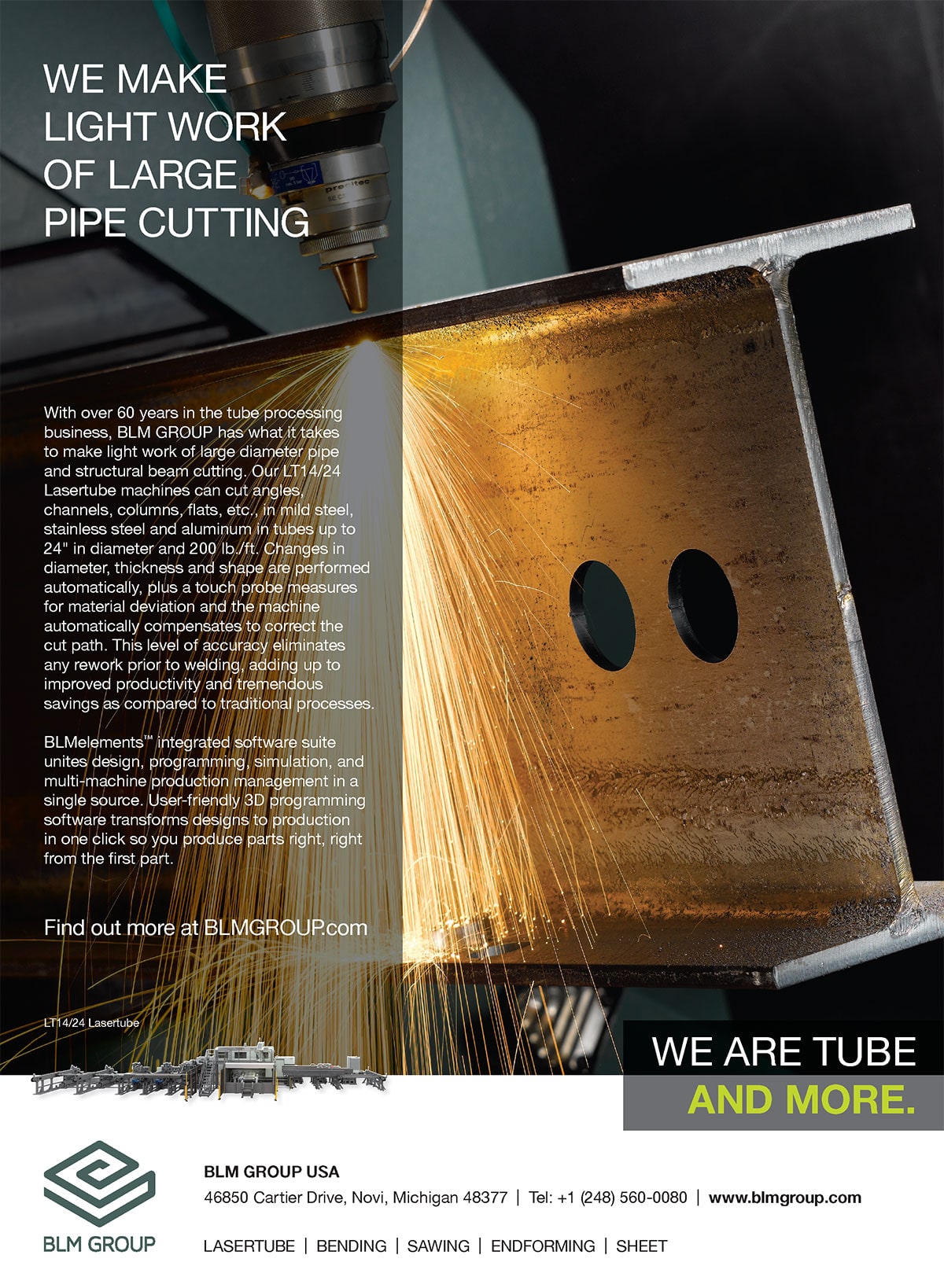

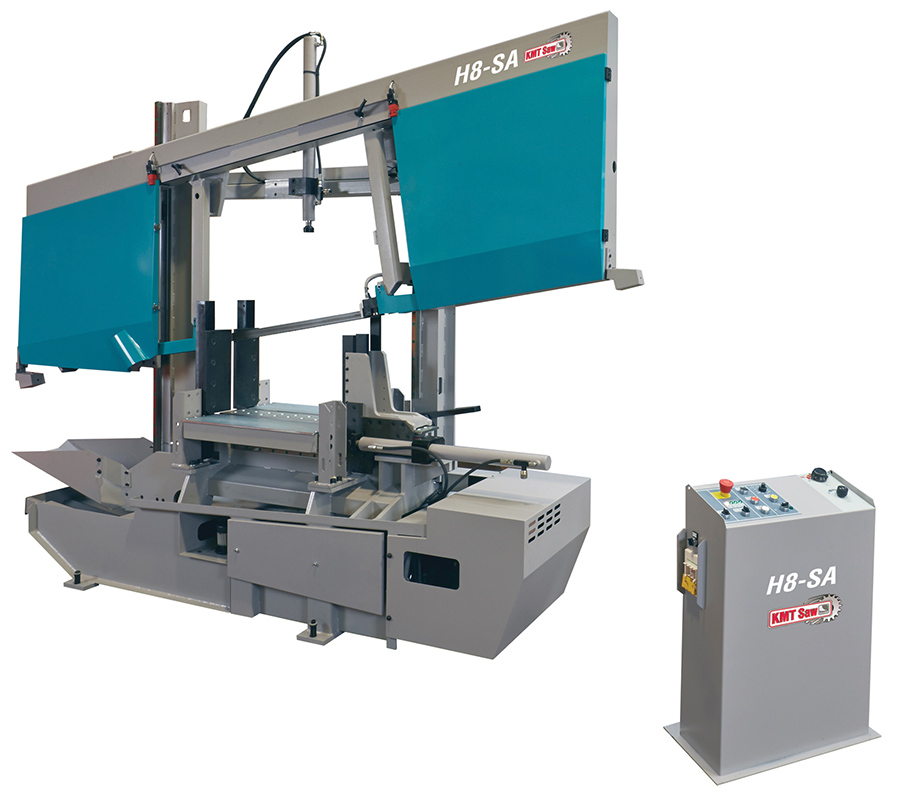

In Syracuse, New York, Elevator Interiors Inc.’s owner, Joe Piepho, found his operations were hindered by other people’s schedules. Rather than farm out cutting jobs, Piepho began to hunt for equipment that would give the elevator parts manufacturer the ability to cut components efficiently and cleanly in house.

he 2005 film “Dreamer” was inspired by the true story of a thoroughbred racehorse that broke her leg and came back to win the Turfway Breeders’ Cup. When asked about her bold decision to nominate the filly for the race, owner Cale Crane said, “It’s a long shot … but why not Sonador? Why not us?”

Brookings, South Dakota, residents Don Deibert and Jeff Jacobson asked themselves a similar question when they couldn’t find the right job shop to produce sheet metal assemblies for their employer, a local manufacturer. After drafting a business plan, the two men formed Counterpart Inc. in 1995, and began making parts for their former employer with little more than a drill press, cold saw and ironworker.

Advertising material due: 7/3/20

agic is the art of illusion, aided by sleight of hand, deceptive devices and misdirection.

When it comes to fluid-formed parts, industrial users might have trouble believing what they see, but Paul Benny, CEO of FluidForming Americas, says, “There are no magic powders or mirrors. It is pure and simple physics that results in a highly repeatable, very accurate, cost-effective part.”

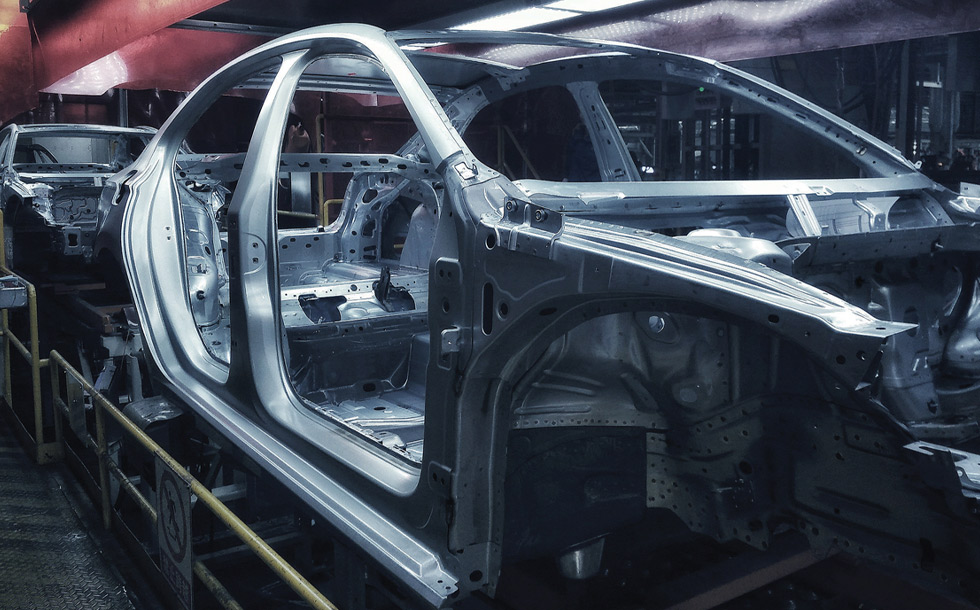

Founded in Hartsville, Tennessee, in 2014 as a German company’s North American subsidiary, FluidForming’s customers include Mercedes-Benz, BMW and Whirlpool Corp. Other end users run the gamut from aerospace, agricultural machinery and alternative energy to automotive and medical equipment.

n Fenton Mobility Products Inc.’s world, a latch is the most critical component in seat configurations for vans and other vehicles equipped to accommodate wheelchairs. High-precision waterjet cutting with the right abrasive makes it possible to achieve the necessary quality.

Fenton Mobility Products designs and manufactures seat bases that ensure wheelchair passengers’ safety in vehicles. The bases contain the latches that attach to Fenton’s specialized AbiliTrax rail system in vehicles like the Ford Transit van, the RAM Promaster and the Mercedes Benz Sprinter. Fenton specializes in commercial applications for state agencies, public transportation and group homes where longevity, durability and versatility are of the utmost importance along with safety and comfort for passengers.

or 16 hours a day, five days a week, Sawing and Shearing Services Inc. keeps its Amada Marvel 2150A-PC3S vertical tilt-frame saw running. The relentless pace wears on the equipment and, after years of 80-hour weeks running, it eventually is replaced in order to start the process anew.

Through the years, the machine’s controls have changed but the model’s cast iron construction remains constant. “We’ve had the 2150 since forever,” says Anthony Sambo, owner of Sawing and Shearing Services. “We just buy new models every few years. Amada Marvel takes back the old one and we don’t miss a moment.”

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net