eld grinding is the removal of excess stock from welds. It’s a process that can produce variable results and impart high stress on employees’ bodies from both the vibration and awkward body positioning, such as outstretched arms.

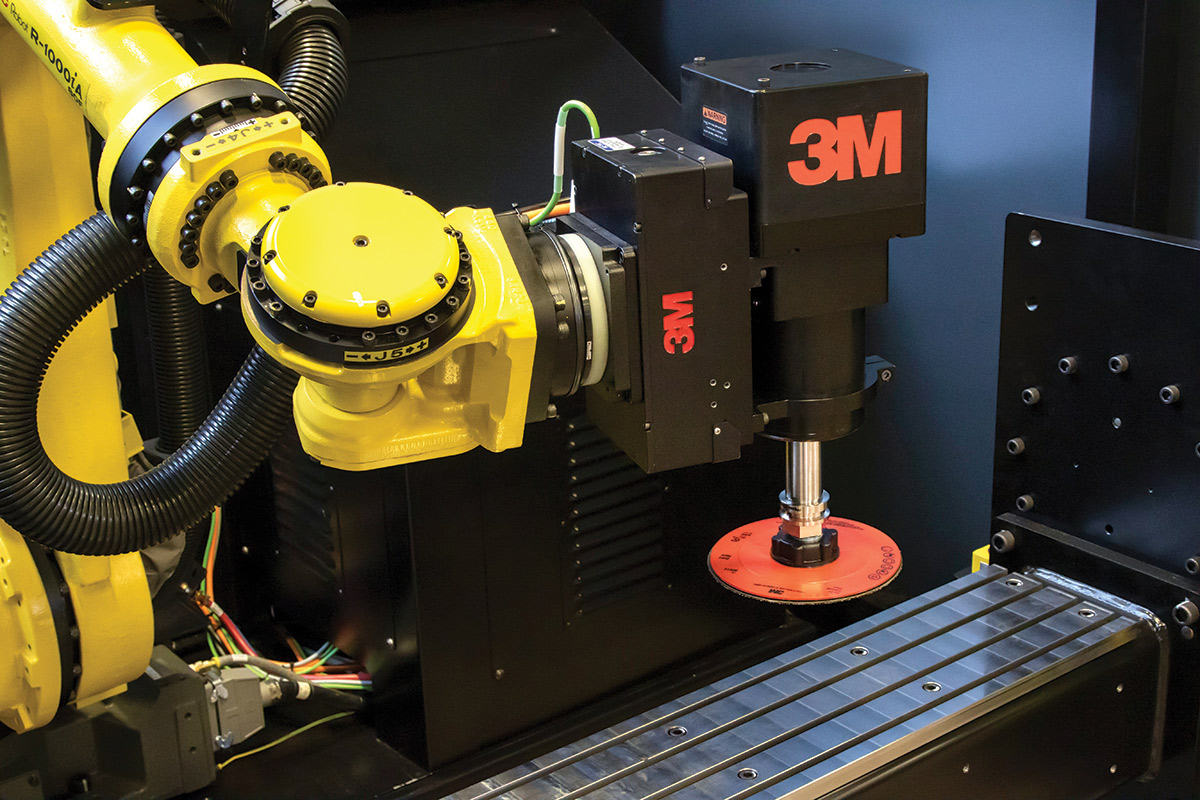

Automating the grinding process traditionally has been difficult; however, Lincoln Electric and 3M have teamed up, combining robotic integration and abrasives expertise to create the Fab-Pak OmniClean system—an all-in-one robotic grinding cell that is pre-engineered to automate and optimize pre- and post-weld applications and has a single base design for easy installation and setup.

Another challenge facing weld grinding departments is the labor shortage, and “a robotic solution certainly addresses that,” points out Ryan Scott, product manager, business development at Lincoln Electric. With the Fab-Pak OmniClean system, “the automation solution has been developed into a standard robot system, making it simpler to install and shortening the timeline to begin using the system,” he adds.

The cell is equipped with either a 3-hp or 5-hp 3M Servo Rotary Tool, and the headstock/tailstock system includes a Fanuc robot equipped with a 3M Servo Rotary Tool and 3M Active Compliant Tool. The 3M Active Compliant Tool applies the correct amount of force for optimal grinding performance for specific applications and finishes. The 3M Servo Rotary Tool maintains consistent speed and horsepower when the abrasive is grinding.

Each cell comes with an abrasives starter pack with the choice of 3M Cubitron II Fibre or Scotch-Brite surface conditioning discs, which are designed specifically for weld cleaning. Discs can be stored in the cell’s media change drawer so that everything is within easy reach.

Adding automated grinding can provide a big bang for the buck in a heavy fabrication facility.

Adding automated grinding can provide a big bang for the buck in a heavy fabrication facility.

The reduction of steps is another benefit the system offers. “The biggest one for weld grinding is eliminating the use of random orbital sanders in a manual process. Generally, the weld is removed with a fiber disk or a flat disk followed by a random orbital sander to break up the deeper scratches so they can’t be seen through paint or powder coating. Using the robotic cell—because of the consistency of the servo motors and the coverage it achieves—reduces the number of steps needed,” says Naatz.