Abrasive Process Solutions Group, Norton | Saint-Gobain Abrasives

reater demands are being put on North American manufacturers to deliver high-quality products faster, all while facing skilled labor shortages. It is easy to see how proving out the most efficient abrasive process solutions, and in many cases automating them, is critical for success.

For over 130 years, Norton | Saint-Gobain Abrasives has worked collaboratively with its customers to solve tough grinding challenges. A recent extension of the Norton application engineering group is a new program called Norton Abrasive Process Solutions (APS). The APS team provides abrasive process development, optimization, automation and in-house testing. APS services could involve research and testing of new abrasives to improve quality or throughput, or it could be trying an entirely new and customized process for customers.

Testing and proving

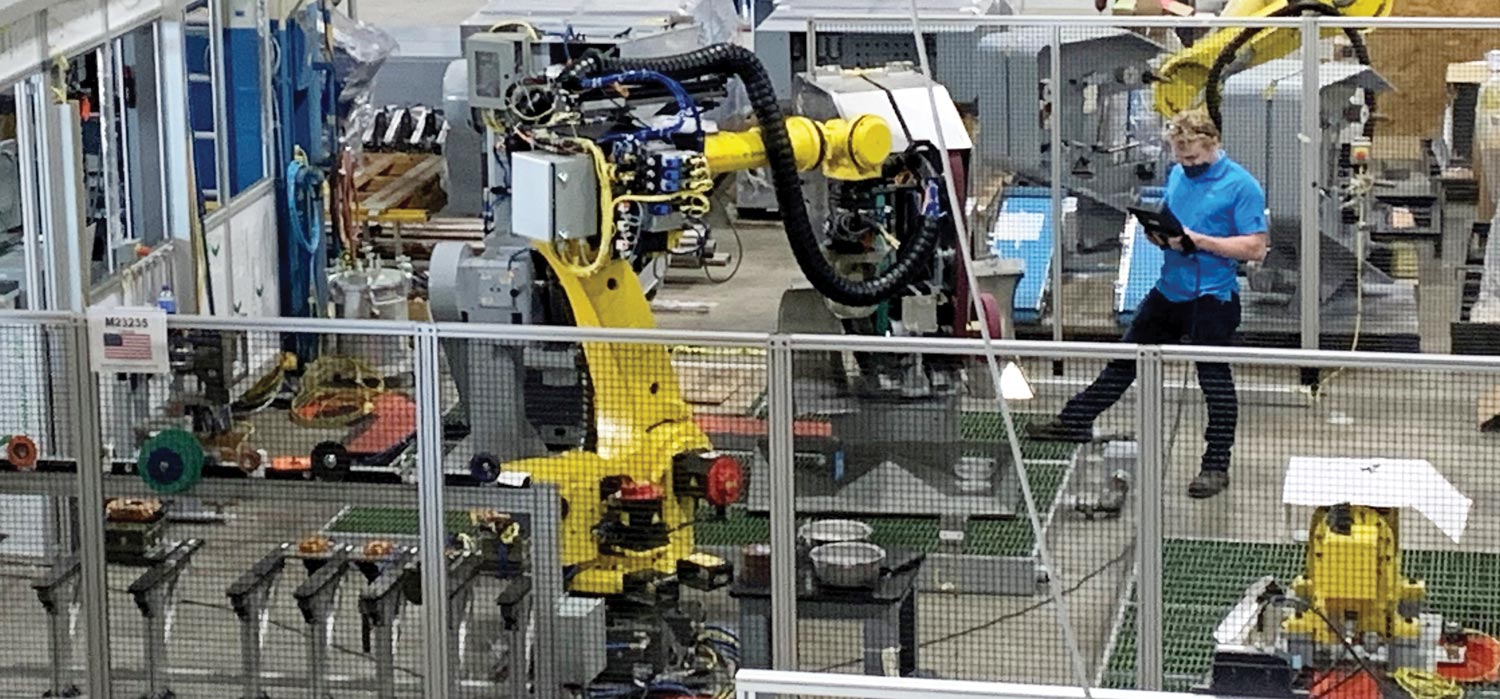

The lab features a FANUC R2000iC robot with a 210-kg. load capacity that allows the testing team to perform processes using nearly any size part or tool. The force sensor-capable robot performs in a multi-capacity role, meaning it is fitted with an end-of-arm gripper to allow for part-to-media processing, as well as ATI Industrial Automation tool changers that use traditional hand tools to perform abrasive-to-part processing.

The Acme Manufacturing integrated robotic-centered process development system includes a programmable pivot table, 6-in.-deep coolant pans, Dynabrade abrasive tools, ATI toolholders and radial compliant devices. Push Corp. spindle motors and compliance slides, as well as two heavy-duty grinding heads, are also in the mix, in addition to a programmable pivot head with dual belt and wheel. Belts, cut-off wheels, and grinding wheels for example, can all be accommodated on the stacked head for part-to-media applications that require heavy pressure such as casting cut-off and gate grinding. A side-by-side spindle head can use two belts and up to four radial wheels, which can produce high surface finishes by buffing or using filament brushes.

In another APS project, an automotive component manufacturer making extruded aluminum truck parts needed a better finishing solution, moving away from off-hand finishing to an automated process to improve output and safety, while maintaining a fine finish. They were also seeking a way to improve productivity by reducing the number of finishing steps. The Norton APS team was able to assist the manufacturer as well as the system integrator with an automated solution. Various abrasive product types and grit sequences were tested, ultimately determining the best products for the application.

The APS team helps metal fabricators and production grinding operations identify and optimize the best abrasive process solution, and in some cases demonstrate how a robotic setup can drastically increase productivity. Robotic arms can be used in instances where manual grinding is not safe or realistic. Robots can also be more cost-effective and help alleviate the stresses of workforce shortages. Equipped with a verified turnkey solution, manufacturers can then contact an automation system integrator to implement the solution and avoid costly trial and error at the integrator level.