ccording to a Tanzanian proverb, “the wind does not break the tree that bends.” It’s a concept the Beckwood Corp. understands. The hydraulic and servo-electric press builder has had to adapt to helping customers do business in the midst of a pandemic while finding new ways to service its machines and continue to educate the industry about trends affecting stampers.

ccording to a Tanzanian proverb, “the wind does not break the tree that bends.” It’s a concept the Beckwood Corp. understands. The hydraulic and servo-electric press builder has had to adapt to helping customers do business in the midst of a pandemic while finding new ways to service its machines and continue to educate the industry about trends affecting stampers.

Now, with trade shows canceled and travel restrictions in place for most of the year, it has reemphasized the need for us to have a strong digital presence and get creative with virtual platforms. We’ve had to find different avenues to replace the physical interactions that aren’t possible right now.”

While COVID-19 has impacted capital equipment budgets, manufacturers’ needs for machine uptime and efficiency have escalated. “Customers began reaching out to us,” says Dixon. “Instead of new presses they were looking for Plan B. As a result, quotes and orders for our electrical and hydraulic retrofits have increased dramatically.”

In the wake of COVID-19, we knew we needed to be ready to respond to the industry’s needs.

In the wake of COVID-19, we knew we needed to be ready to respond to the industry’s needs.

For extensive retrofits, cost can be a factor if the machine must be dismantled and shipped. “We offer retrofit customers a number of options,” Dixon continues. “They can choose to send the entire machine or just portions of it to our facility, or if state restrictions allow, we can send a team of technical specialists to perform the upgrades on their factory floor.”

Another mainstay pandemic trend is manufacturers that have chosen to keep their facilities and production floors closed to outside visitors.

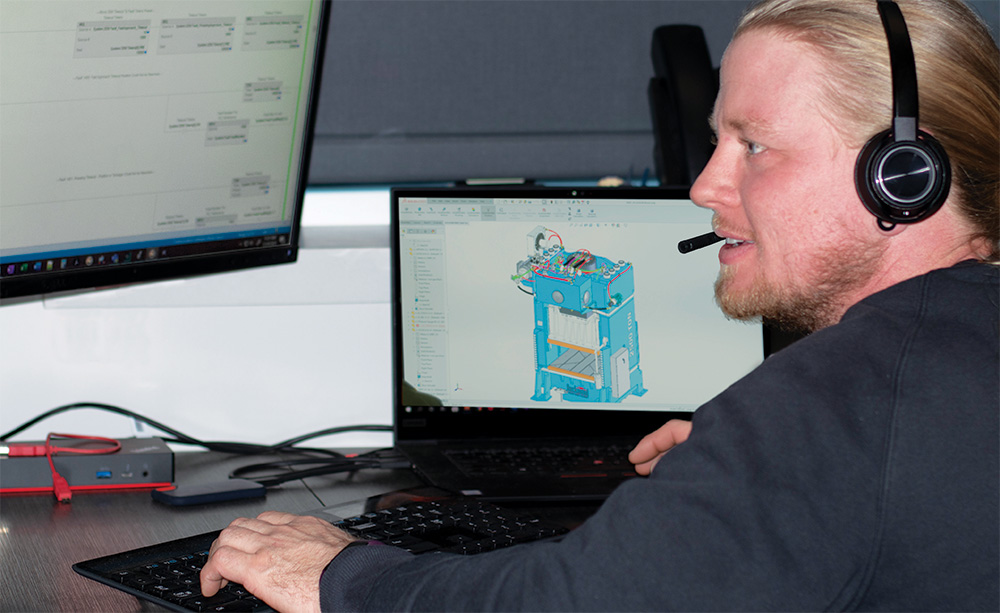

“This has proved to be a challenge for both the OEM and the end user,” says Dixon. Beckwood has built its business by being a technology and service-oriented company, so it developed its Factory Connect PressLink Module. The proprietary feature uses a standard internet connection to remotely join a Beckwood technician with a press in the field. Once connected to the machine, the specialist can troubleshoot, diagnose the problem and give step-by-step instructions to an on-site representative on how to fix the issue. A fabricator’s ability to connect its presses with factory technicians 24/7 saves time and the costs associated with unplanned downtime.

Beckwood can also use the module to perform machine program modifications and upgrade or monitor processes. “We wanted to be able to connect virtually to any machine we’ve installed so that we can reduce the number of on-site visits each year and ultimately reduce costs and downtime for our customers,” Dixon says. “Ten years ago, we began installing PressLink on a case-by-case basis. We saw the benefits almost immediately, so we decided to include it as a standard feature. Today, we don’t ship a machine out without it.”

Beckwood technician changes oil filter during 6-month press checkup for customer.

Social distancing requirements for the shop floor and unstable operator attendance have manufacturers looking at automation as part of the retrofit and upgrade work they are sourcing from Beckwood.

“We recently sold a quick die change package because the customer wanted to make their changeover process more efficient,” says Dixon. “Another customer wanted to convert their existing press into a rubber pad press with a shuttle system to support easy part loading and unloading. Our ability to evaluate existing processes and offer customers ways to increase throughput with minimal upfront cost has been hugely successful during the pandemic.”

“One of the big issues that customers talk to us about is that they weren’t aware of how much they were spending on unpredictable maintenance, especially for legacy equipment,” Dixon says. “In response to this, we implemented a bumper-to-bumper service package at a fixed price that allows customers to budget for everything they need to keep that machine up and running.”

Beckwood introduced its fixed-cost annual maintenance package in 2019. It includes six and 12-month machine inspections, free remote support, 24/7 priority access to technicians, and free replacement components.

Beckwood’s technical support team is also able to customize a preventive maintenance package that supplements a customer’s existing efforts or replaces in-house maintenance for press equipment.

While 2020 was a different year for the press builder and its customers, Dixon contends that “COVID-19 didn’t create new trends but rather just accelerated the journey people are already on in both their personal and professional lives.

“If you think about it, online shopping and curbside grocery pickup were already in place before the pandemic,” he says. “We’ve seen the same thing in manufacturing. Customers were already trending toward things like automation and maintenance programs supported by OEMs. COVID-19 has just pushed our industry down that path faster.”