diversified portfolio can cushion an investor from unexpected market booms and crashes. The same level-headed approach allows C4 Welding to continue serving customers despite a challenging 2020. “We try to maintain no more than 30 percent of our business in any one market,” says Henry “Bunky” Ewers, director of weld operations at the Sauk Rapids, Minnesota-based welding and manufacturing company. “In today’s industry, diversity in skill sets is king.”

“We are constantly looking for new opportunities so that we are not negatively affected when one market has a lull,” he adds.

In August 2020, C4 decided to invest in a new saw. “The decision was multifold,” Ewers says. “Demand from customers along with it being a strategic decision to lower costs, the new saw has allowed us to buy more steel directly from the steel mills, which helps us with pricing in competitive markets.”

“It is economical with good dealer support, and there are many Cosen saws in the area with good reviews,” Ewers says. “The Cosen is very universal and adaptable, whether it be angled cuts, bundled cutting, large tube cutting or even using custom fixtures to reduce machining time.”

We can buy more steel directly from the steelmills, which helps us with pricing.

We can buy more steel directly from the steelmills, which helps us with pricing.

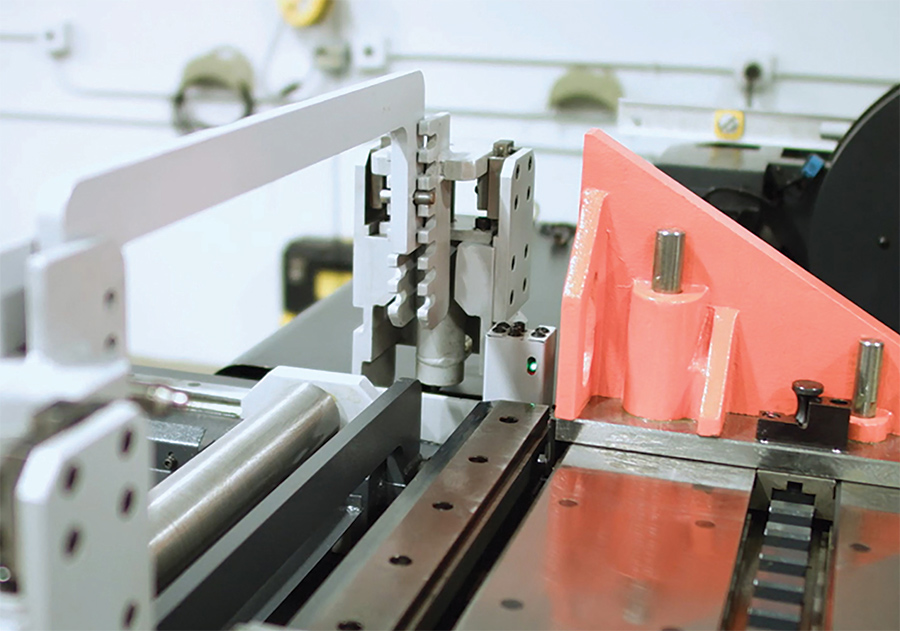

“Key design features of this model are that it has a wide and solid base, which helps absorb vibration, thus saving blade life,” says Hayden Peterson, marketing specialist at Cosen Saws, Charlotte, North Carolina. “A 10-ft. tethered control panel and user-friendly HMI touchscreen allows the operator to move the work station to a different location when needed.”

The saw also includes a save-a-blade feature, which is an adjustable head cant that moves from 0 to 5 degrees and an automatic ball screw-powered side-feed table that has a single stroke of up to 57 in.

C4 wanted easy access to customer service and Cosen has a vast outside sales network comprised of distributors, regional sales managers and sales representatives for North America and Mexico for pre- and post-sales support. “It is important not only to focus on the sales network but also service and parts as well,” Peterson says. “Cosen was able to support C4 when they had minor issues in the beginning by providing the service and parts support to get them up and running.”

Once Cosen has an overview of a customer’s production process and learns what it is they are producing, they can then determine a customer’s cutting needs. “This includes needed cutting capacity, material type, frequency at which they need to cut, whether mitering capabilities are needed, etc.,” says Peterson. “Once enough information has been gathered, our sales teams will then present the best options for that specific cutting need and can move forward with an extensive quote detailing machine specs and features, an investment summary and lists of standard and optional accessories that come with the saw.”

C4 has dedicated personnel for its Cosen AV-2026NC and others who are cross-trained. “The training from Cosen was helpful as well as the manuals,” Ewers adds, noting the saw has been useful for cutting internal and external piping for pressure vessel tanks, including many types of structural components. “We can bundle cut and perform programmable angle cuts.”