ith demand on the rise, Marley Engineered Products in Bennettsville, South Carolina, found it needed to run four punch machines in continuous shifts to keep up.

“We were in the process of replacing some 30-year-old punching equipment, and it made sense to look into updated software to link all our machines together,” says Guy Mulee, manufacturing engineering and maintenance manager.

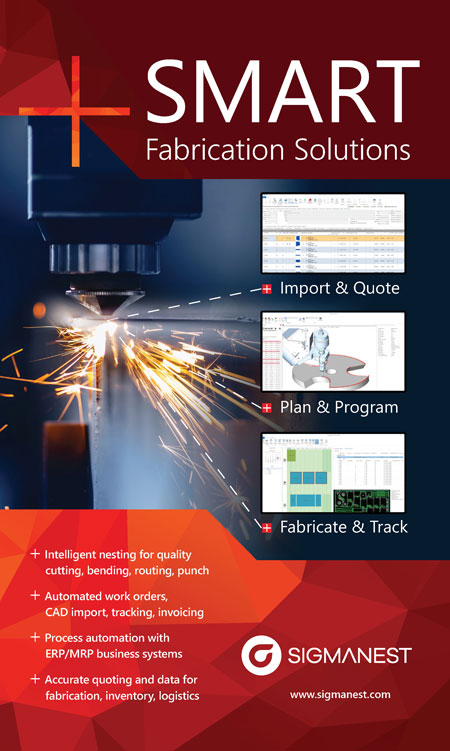

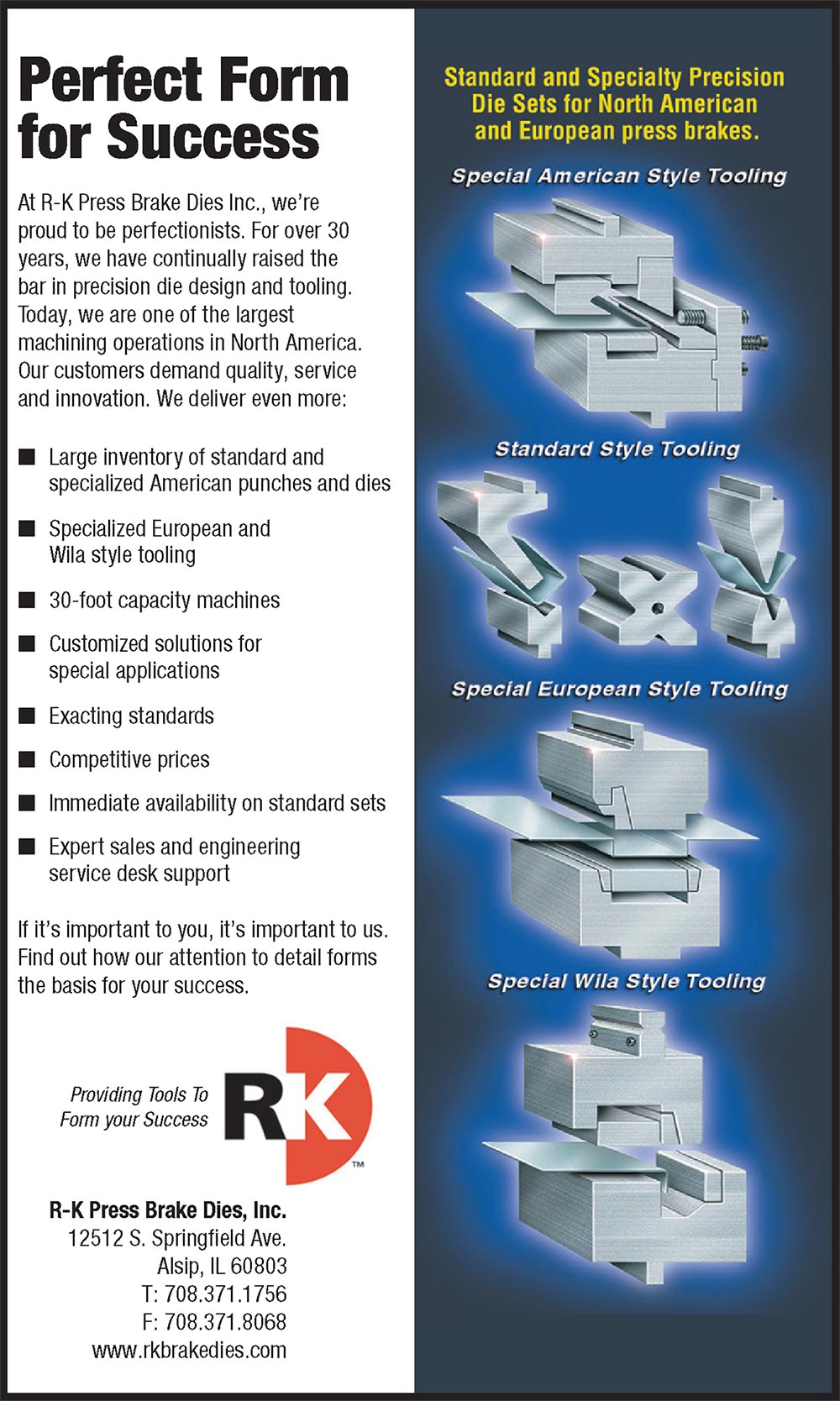

While replacing equipment, Mulee and CNC programmer Damien Warren, noted that Trumpf equipment used Metamation software, a product compatible with other equipment brands. “We realized we could program our Trumpf Trumatic combination machine, TruBend press brake, and also our LVD Strippit punch,” Warren says. “It didn’t make sense to use another third-party software when Metamation is Trumpf software and would give us the ability to program some of our other punching and forming equipment.”

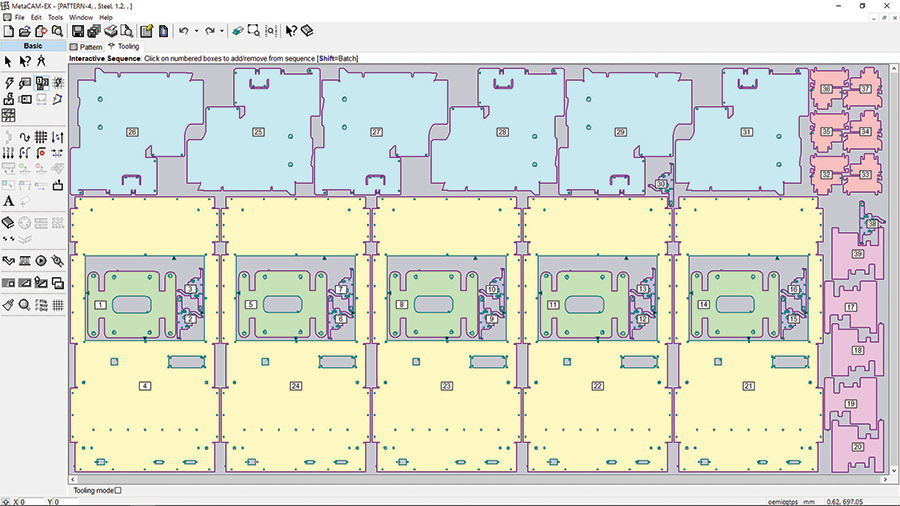

Marley Engineered Products uses MetaCAM for its Trumpf combination machine, Strippit Punch, and Flux Bend for its Trumpf press brake. They are currently in the process of implementing the software onto a Cincinnati press brake. The heating system manufacturer produces its metal components using a multistep stamping, forming and fabrication production process.

The 2D and 3D CAD module in MetaCAM is developed from the ground up. “The module is designed specifically for sheet metal fabrication,” says Anupam Chakraborty, manager of software products at Metamation. “The interface is very simple. Other software products use an outside engine for drawing/designing and were developed for multiple applications and not specifically for sheet metal.”

We have reduced our shift requirements by 15 to 20 percent.

We have reduced our shift requirements by 15 to 20 percent.

“Software installs are very lean,” he continues. “The software does not consume a lot of computer resources and is faster than other software suites.”

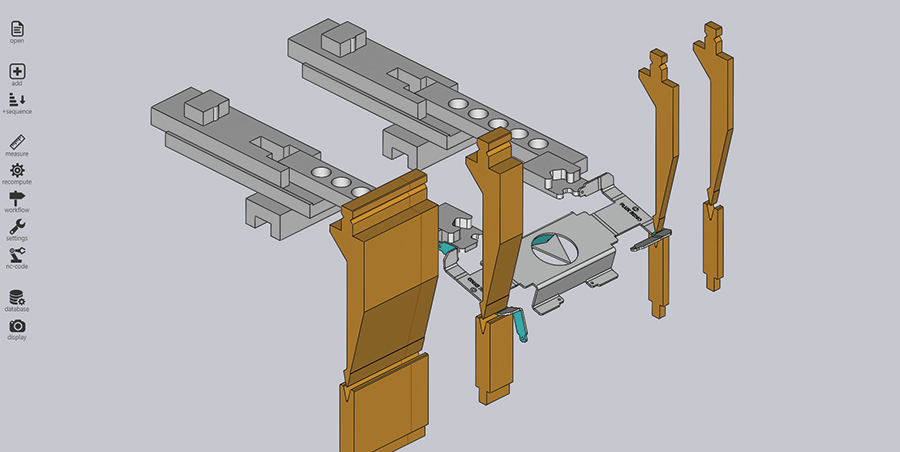

The simulation of the tooled part is displayed as a graph for the operator to see each bending step. The Flux Bend module can handle multiple parts and assemblies quickly and simultaneously.

The CNC punch department is no longer the source of the line’s bottleneck. “We can produce everything we need on a normal schedule,” Mulee says. “But, when we need to, we’re able to make adjustments for when schedules get tight and need to be flexible.”

Metamation’s Chakraborty says since the pandemic began, customers are looking for software that “will work right out of the box and support many critical features of the new age machines.”

Customers want the capability to support a wide variety of machines with planning, scheduling and manufacturing to cut back on any wasted resources. “The pandemic has increased the demand for MetaCAM Enterprise Solution (MES System), which integrates many aspects of fabrication and also the ability to operate remotely when necessary,” he adds.

Marley Engineered Products has instituted strict hand washing, mask wearing and social distancing policies. “Like many companies, MEP requires flexibility for our team that still allows us to meet the needs of our customers. So, tools like MetaCAM are a big help, and it has helped us further improve cross-training.”