From the Editor

moved into a new house in January 2021 after the original structure was destroyed by an EF4 tornado in 2019. I lived with my parents during the rebuilding process, which created an environment conducive for conversations like the one I recently had with my 90-year-old father about his days at the National Cash Register Co. (NCR)

My dad completed a 4-year stint with the U.S. Navy aboard a destroyer during the Korean War. When he returned to Dayton, Ohio, following an honorable discharge, he got a job at Leland Electric making parts for electric motors. He soon migrated to NCR. It was especially exciting for me because it meant our family had access to Old River Park and its swimming pool. Equipped with diving boards, water slides and an ornate tower that divided the shallow and deep ends, the pool was one of the largest in the nation.

Features

/customfabricator

/deburring

/waterjet

evitalizing production in the evolving post-COVID market is a common reality most manufacturers must face. Decision-makers are discovering that the use of high-performance press-tending robots can provide the robust ROI needed to make the leap to robot automation worthwhile.

Anirudh Udupa

Researchers previously demonstrated that the application of a permanent marker or Sharpie, glue or adhesive film made it easier to cut metals such as aluminum, stainless steels, nickel, copper and tantalum for industrial applications. Marking the metal surface to be machined with ink or an adhesive dramatically reduced the force of cutting, leaving a clean cut in seconds. Researchers now know how these films achieve this effect.

n 1850, Isaac Singer invented an affordable sewing machine that could push thread through fabric at 800 stitches per minute. In 1873, he bought 32 acres in Elizabeth, New Jersey, and built the Singer Sewing Machine Manufacturing Co. The main assembly building was almost half a mile long. A forge, foundry and 6-mile-long railroad completed construction of the complex. Singer quickly grew to a workforce of 6,000 and its factory floor space soon expanded by nearly 100 acres. At the turn of the century, the brand introduced the first practical electric sewing machine. Other improvements followed. In 1941, with America poised to enter WWII, employment at Singer had reached nearly 10,000 people.

SweBend’s handheld wireless Bluetooth control allows the operator to monitor the rolling operation from any angle.

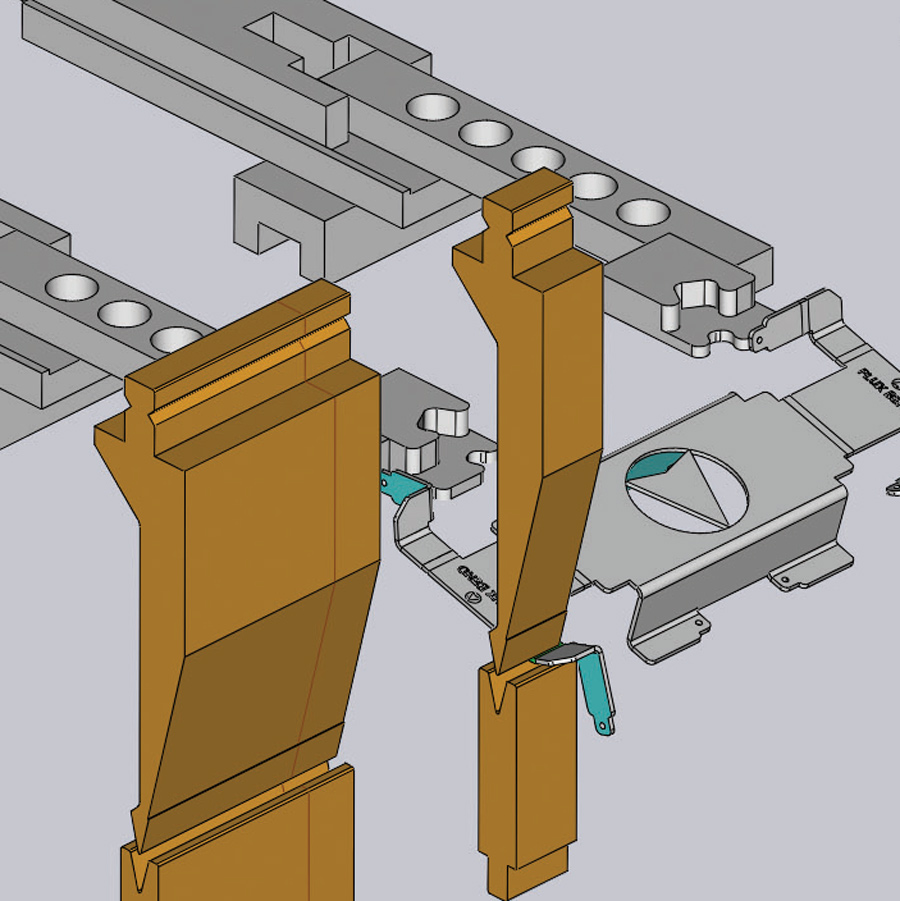

he motivational one-liner, “If it was easy, everyone would do it,” is a phrase that is often repeated to those who are treading a difficult path for a worthwhile pursuit. Linders Specialty Co. has put its own spin on the expression. “We like to say that ‘if it were easy, somebody else would do it,’” says Owner and President Vince Linders. “One of our strengths is difficult, complex or intricate projects that require processes or machines that you typically won’t find at other shops. Our CAD capabilities and equipment allow us to take those projects and develop tooling and fixtures that can monitor each step for consistent, accurate parts.”

ccording to a Tanzanian proverb, “the wind does not break the tree that bends.” It’s a concept the Beckwood Corp. understands. The hydraulic and servo-electric press builder has had to adapt to helping customers do business in the midst of a pandemic while finding new ways to service its machines and continue to educate the industry about trends affecting stampers.

ccording to a Tanzanian proverb, “the wind does not break the tree that bends.” It’s a concept the Beckwood Corp. understands. The hydraulic and servo-electric press builder has had to adapt to helping customers do business in the midst of a pandemic while finding new ways to service its machines and continue to educate the industry about trends affecting stampers.

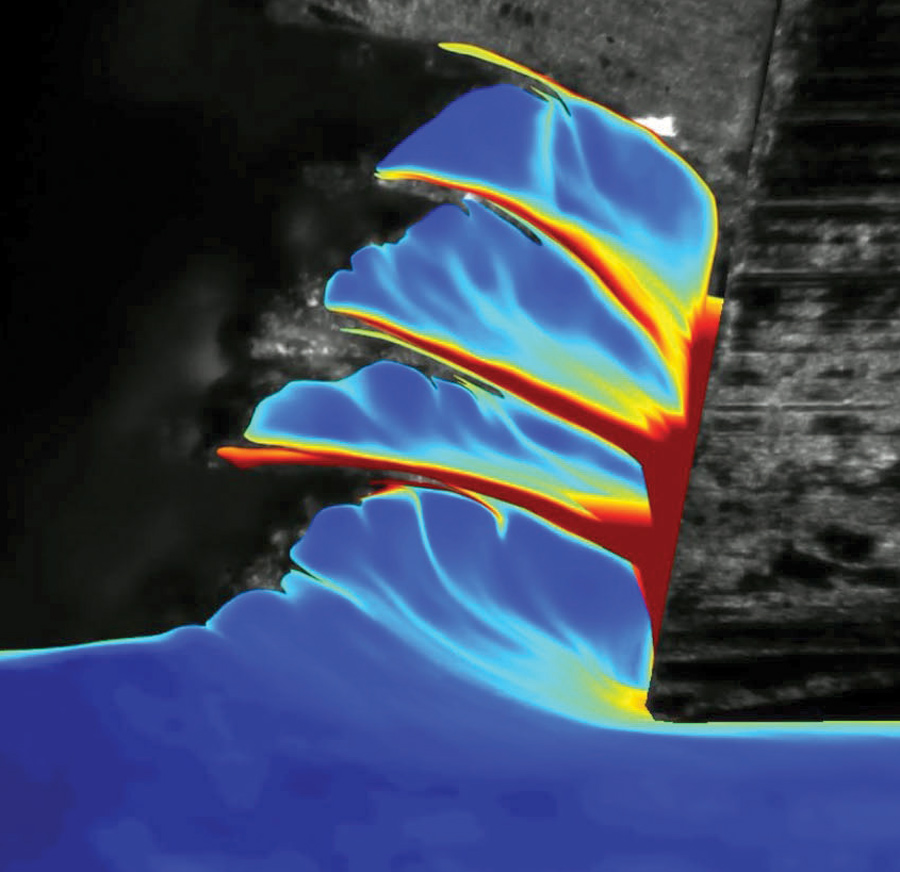

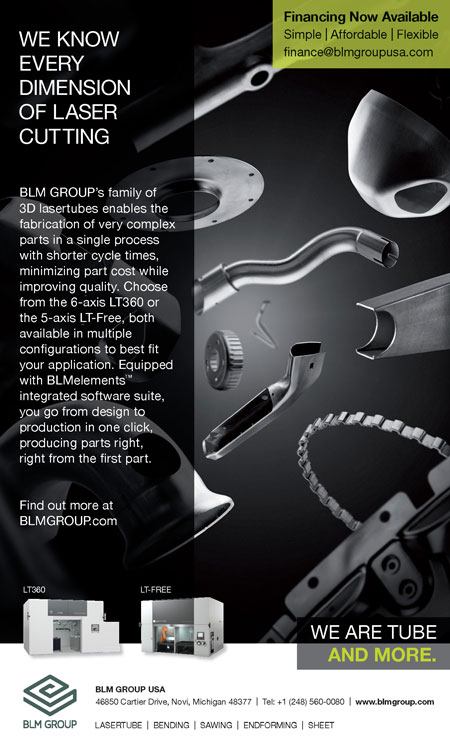

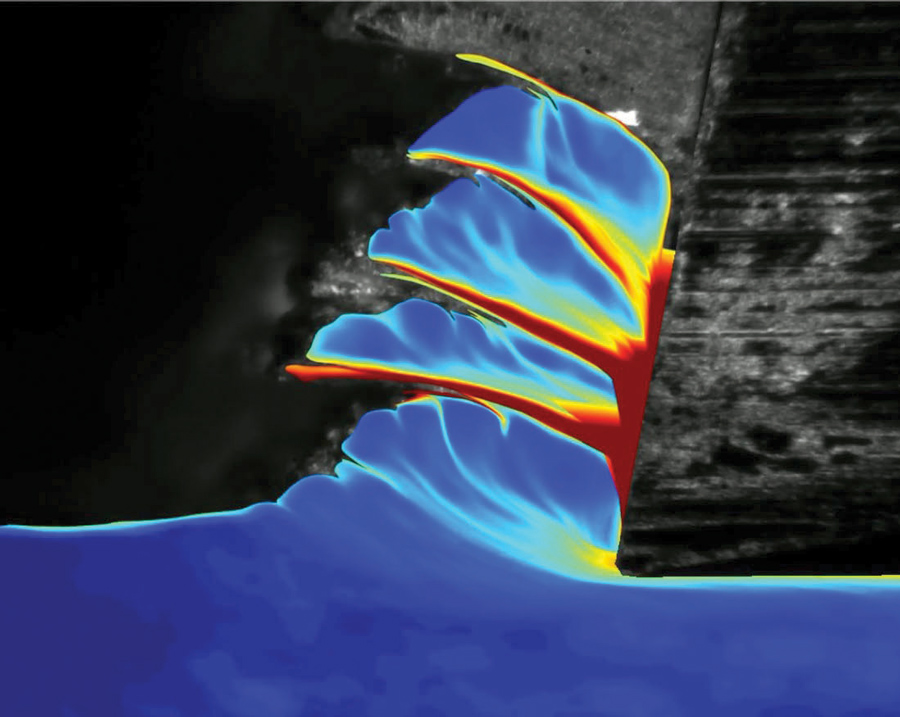

Below: Heat shields produced on the BLM GROUP LT-FREE.

t Sharpe Products, each day brings with it a wide range of tasks. “We never know what types of jobs we’re going to get from fabricators or other customers,” says Paul Krickeberg, president and CEO.

The industrial and commercial tube and pipe bending, laser tube cutting, and custom fabricator needs to be able to cut holes into tubing before and after the bending process. “No matter how many features you’re able to cut before bending, there are still parts where notching, coping or slottings must be done after the bend, whether due to location or complexity,” Krickeberg says.

Most recently, Sharpe purchased the LT-FREE 5-axis laser cutting system from BLM GROUP. The ability to process a wide range of parts is essential for the company. The LT-FREE’s dual work chambers and index tables allow users to load and offload parts while the machine is cutting, saving on production time. The part is manipulated by the robot, which makes it possible to cut geometries to specification on complex-shaped parts, such as the radius of a pre-bent tube or 3D hydroformed or stamped part.

Combilift telescopic Straddle Carrier entering the Steel LLC building.

ess than 20 miles outside of Atlanta, a massive collection of trailer beds once canvassed six acres of land. Each trailer bed held wide flange (I-beams), channels and HSS tubing, ranging from 40 to 50 ft. long and weighing 15 to 600 lbs. per ft. Overhead cranes were the only way to maneuver the bulky steel pieces, and the rented trailers were a necessary expense.

ith demand on the rise, Marley Engineered Products in Bennettsville, South Carolina, found it needed to run four punch machines in continuous shifts to keep up.

“We were in the process of replacing some 30-year-old punching equipment, and it made sense to look into updated software to link all our machines together,” says Guy Mulee, manufacturing engineering and maintenance manager.

While replacing equipment, Mulee and CNC programmer Damien Warren, noted that Trumpf equipment used Metamation software, a product compatible with other equipment brands. “We realized we could program our Trumpf Trumatic combination machine, TruBend press brake, and also our LVD Strippit punch,” Warren says. “It didn’t make sense to use another third-party software when Metamation is Trumpf software and would give us the ability to program some of our other punching and forming equipment.”

diversified portfolio can cushion an investor from unexpected market booms and crashes. The same level-headed approach allows C4 Welding to continue serving customers despite a challenging 2020. “We try to maintain no more than 30 percent of our business in any one market,” says Henry “Bunky” Ewers, director of weld operations at the Sauk Rapids, Minnesota-based welding and manufacturing company. “In today’s industry, diversity in skill sets is king.”

View Index

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matt LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.