fforts to improve automotive fuel efficiency for gas-powered vehicles, along with the rise of electric cars, are creating a need for lighter weight materials in passenger vehicle designs. Using aluminum for certain body components, in particular, has proved its value in reducing vehicle weight without compromising strength and durability.

There are challenges, however, when welding the aluminum alloys to make body-in-white (BIW) parts. A new type of fiber laser technology solves the most serious challenge—namely “hot cracking”—when welding 6XXX series aluminum alloys.

The solution in the past has been to employ filler wire of a composition which, when introduced into the weld pool, changes the percentages of alloying materials enough to move the process away from the most crack sensitive region.

The solution is therefore to modify the spatial distribution of applied laser power to make the heating cycle more gradual. One way to accomplish this is by using “beam wobble.” That is, operators can rapidly scan the focused laser spot over a small area so it appears to the material to be much larger. But this has the side effects of increasing welding system cost and complexity and limiting weld speed.

A recently developed technology called Adjustable Ring Mode (ARM) fiber laser offers a new solution. Here, the intensity profile of the focused laser spot is modified so that it departs significantly from the traditional, single-peaked Gaussian distribution. This consists of a central Gaussian distribution spot, surrounded by another concentric ring of laser light. This is produced using a specialized delivery fiber that has a traditional circular core surrounded by another, annular cross-section fiber core.

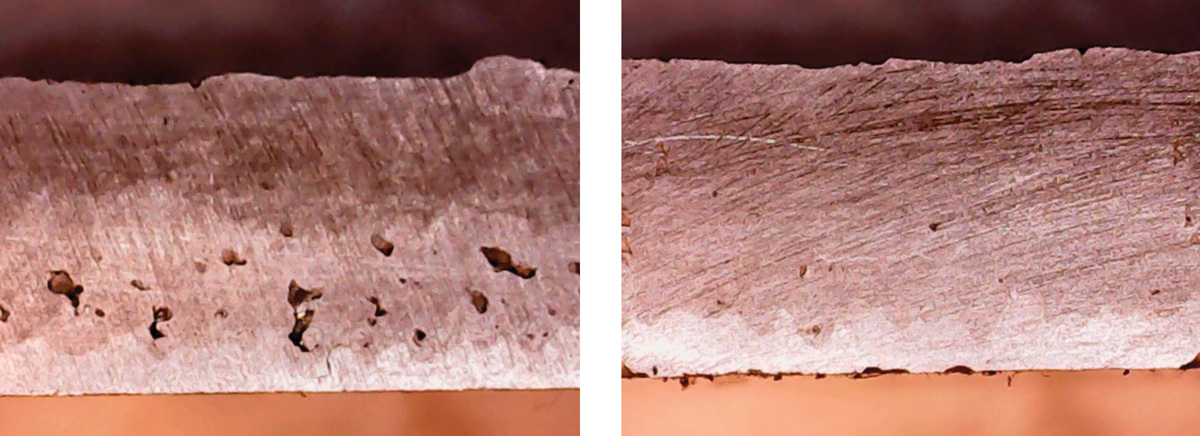

A 1.3-mm-thick top sheet of 5XXX aluminum was welded to a 1.5mm thick bottom sheet of 6XXX aluminum with zero gap. A range of laser powers were used, which delivered either near or full penetration of both sheets. No filler wire or material was used.

In the case of the ARM laser, a HighYAG RLSK Remote welding optic was used for beam focusing, along with a travel speed of 4.5 m/min. (consistent with current production requirements). No beam oscillation was used for either laser.

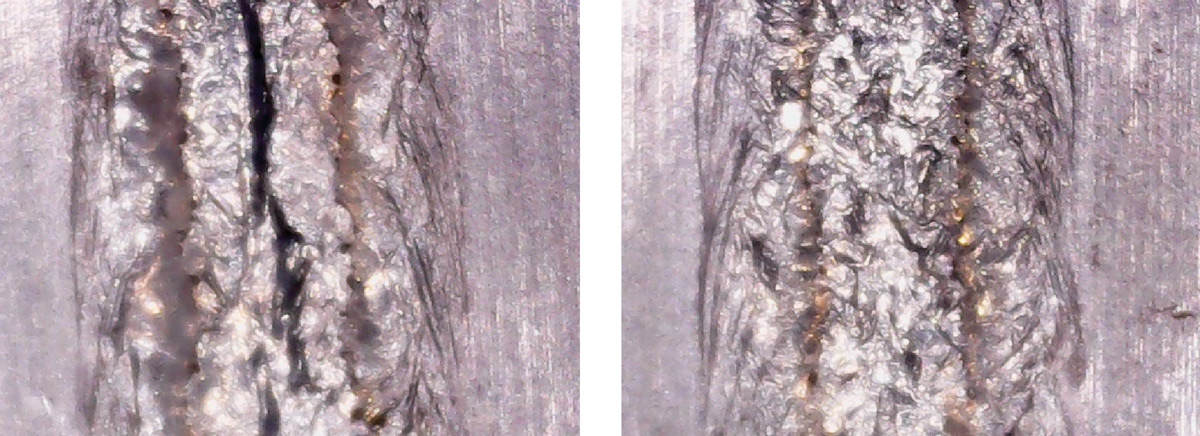

The ARM beam configuration demonstrates the capacity to weld formerly problematic aluminum alloys without hot cracking.

The ARM beam configuration demonstrates the capacity to weld formerly problematic aluminum alloys without hot cracking.

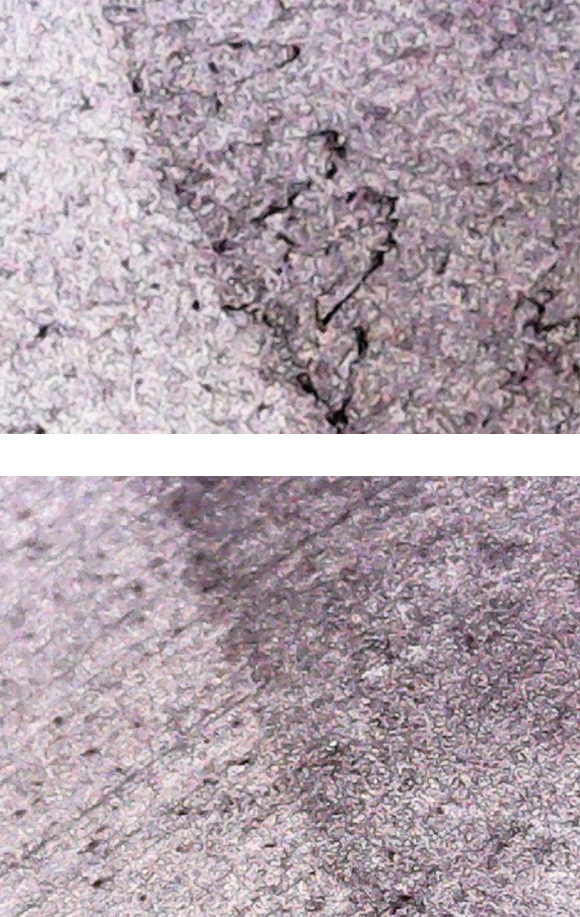

Although best results were achieved with higher total power in the ring beam than the center beam, the focused ring spot is much larger, and therefore its power density is lower. As the leading edge of the ring beam preheats the material, the center supplies sufficient power to perform the actual welding, and the trailing edge of the ring beam post-heats the material.

This sequence maintains the metal at a higher temperature for a longer period than a traditional single laser spot, and provides sufficient control of the heating/cooling rate to prevent cracking.

The ARM beam configuration demonstrates the capacity to weld formerly problematic aluminum alloys without hot cracking, and with a reduction in weld defects. By eliminating filler wire, as well as shielding gas, it is simpler to implement. Finally, this new method supports higher weld speeds than are possible with filler wire.