Tower

Features

/stainless

/abrasives

/laser

Senior Editor

hroughout the country, architects are seriously considering Speedcore technology for their building projects. This recently developed prefabricated system changes how designers, engineers and construction teams approach a project by shifting away from traditional reinforced concrete structures.

This month’s cover story (page 16) focuses on Rainier Square Tower in Seattle which, despite a crane operator strike, viaduct closure and inclement weather, still met its August 2019 timeline. Now, teams are finishing the base of the building and all interior work. With SpeedCore, there is no foundation lay-down stage, where concrete is poured and builders must wait weeks for it to sufficiently harden. Instead, two steel plates are set 24 in. apart by smooth steel bars, which are installed as part of a concrete-filled panel.

orkers who have spent their entire careers in manufacturing have amassed a base of experiential knowledge—concepts that aren’t typically taught in school. When they retire, the knowledge goes with them. THORS eLearning Solutions, a developer of online training and assessment tools for materials, manufacturing processes and manufactured products, is capturing this knowledge and making it accessible to the next generation.

“Prior to THORS, an individual had to learn in person from an expert, so there were constraints on the availability of the experts—and they would also have to have the passion, the content and time to teach,” says Senthil Kumar, founder of THORS eLearning Solutions. “THORS solves that problem by digitizing the knowledge from experts so proximity and availability do not matter.”

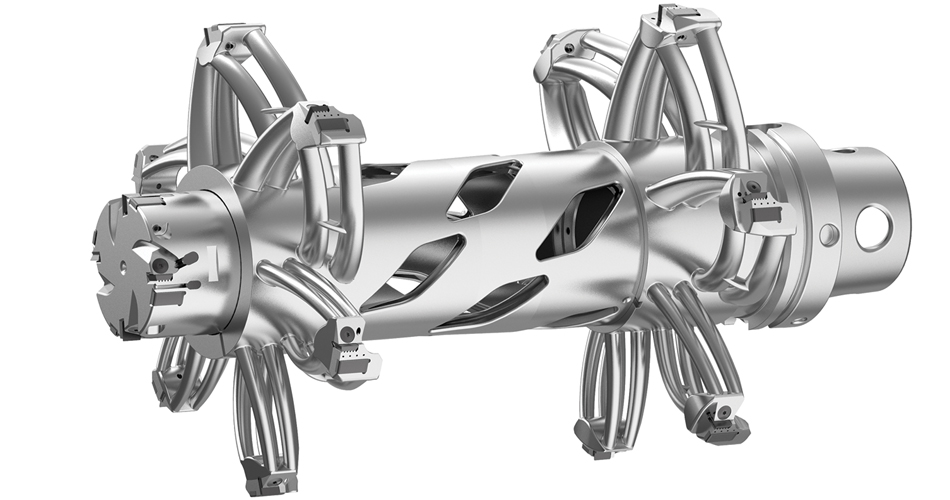

Kennametal, Latrobe, Pennsylvania, 724/539-5000,

www.kennametal.com.

Madison Chemical Co., Inc., Madison, Indiana, 812/273-6000, www.madchem.com.

Francine Bovard, senior technical specialist with Arconic, New Kensington, Pennsylvania, will serve a three-year term on the ASTM International board of directors. Bovard has been with Arconic for 28 years, having previously served as a technical specialist with Alcoa and as a technician with Sandia National Laboratory. An ASTM International member since 2013, Bovard belongs to the committees on light materials and alloys (B07), fatigue and fracture (E08), additive manufacturing (F42), corrosion of metals (G01), and the joint ASTM/NACE committee on corrosion.

DeWys Manufacturing Inc., a fabricator and contract manufacturer in Marne, Michigan, named Mark Schoenborn as president. Schoenborn succeeds C.T. Martin, who served as president for the past five years. Martin will now assume a role on the newly formed advisory board for DeWys Manufacturing.

Michael C. Gazmarian, Insteel Industries Inc.’s vice president, chief financial officer and treasurer, has left the company to pursue other opportunities. The Mount Airy, North Carolina-based company has launched a search for Gazmarian’s successor.

The steel industry has a whole new scope to add to their workload … what was once concrete is now steel.

The steel industry has a whole new scope to add to their workload … what was once concrete is now steel.

ityscapes are constantly evolving. A continuous cycle of razing and new construction, accompanied by a slew of cranes weaving through skylines from Boston, New York, Chicago to Los Angeles and Seattle—where earthquakes make high-rise construction particularly challenging—has caused the industry to question: Is there a faster way?

In August 2019, the final steel beam was added to Rainier Square Tower, “topping it off” as the first high-rise built using SpeedCore technology, a new and faster method of steel frame construction.

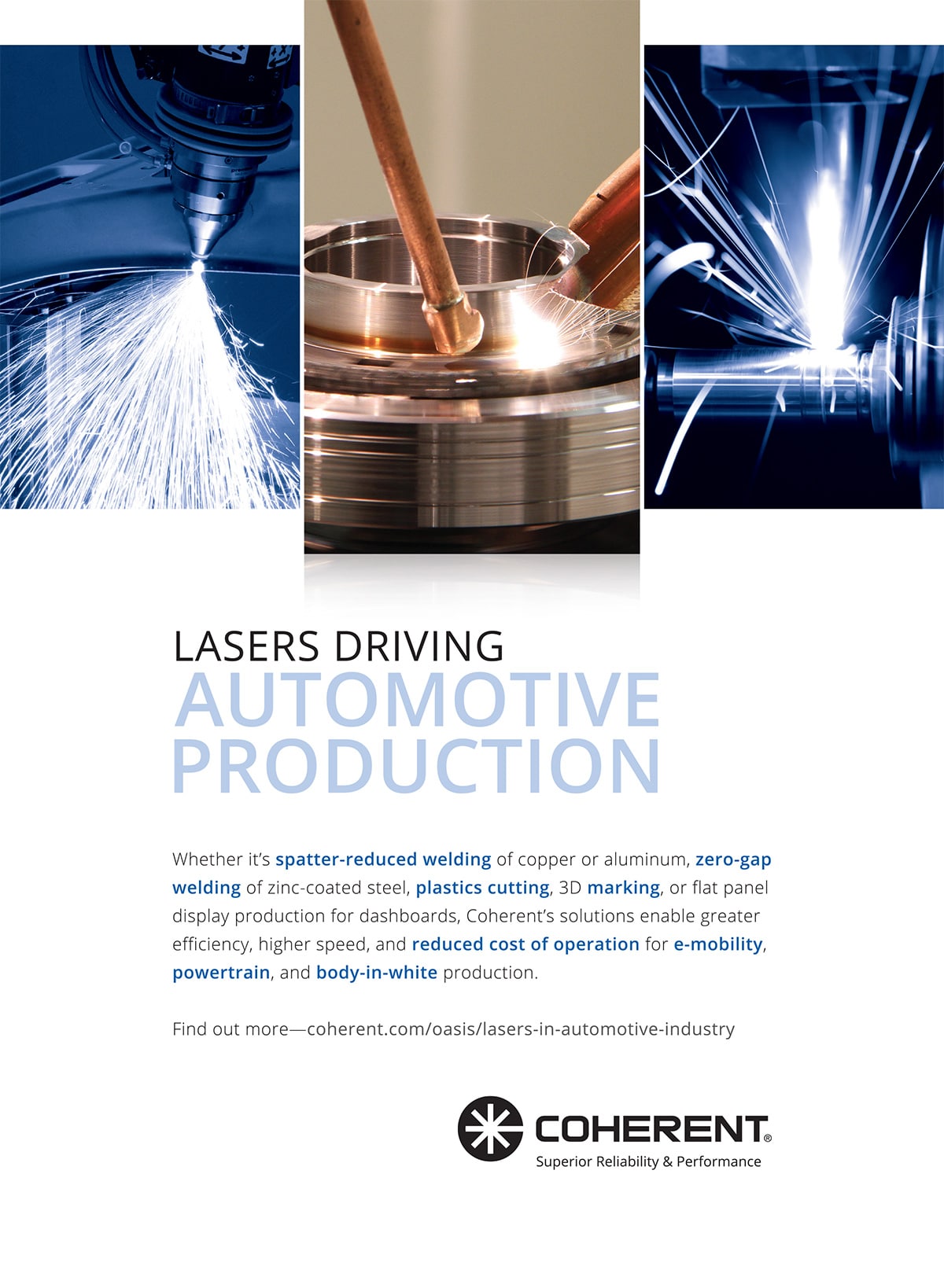

fforts to improve automotive fuel efficiency for gas-powered vehicles, along with the rise of electric cars, are creating a need for lighter weight materials in passenger vehicle designs. Using aluminum for certain body components, in particular, has proved its value in reducing vehicle weight without compromising strength and durability.

There are challenges, however, when welding the aluminum alloys to make body-in-white (BIW) parts. A new type of fiber laser technology solves the most serious challenge—namely “hot cracking”—when welding 6XXX series aluminum alloys.

geometry

geometry

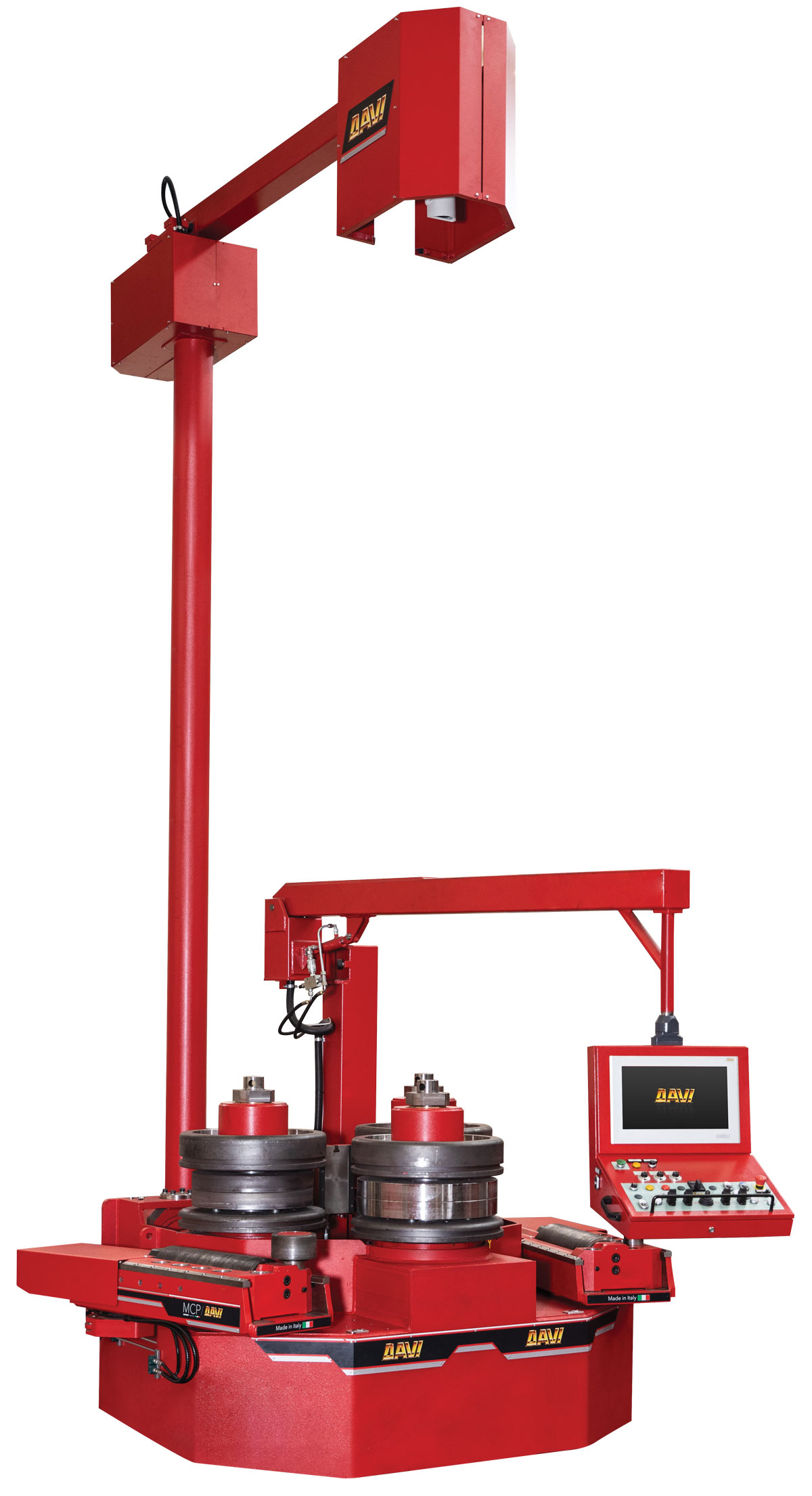

ost people do not listen with the intent to understand; they listen with the intent to reply,” educator and author Dr. Stephen Covey said. Davi took this concept a step further when it designed and built a custom angle roll for Birmingham, Alabama-based Clayton Industries.

The 52-year-old fabricator produces rolled beams, angles and tubes; structural bending comprises 40 percent of its business. The shop’s range and capacity—bending structural beams up to 40 in. wide and plate from 1/8 in. to 6 in. thick by 40 ft. long—gives Clayton Industries a strong base from which to service building and construction clients.

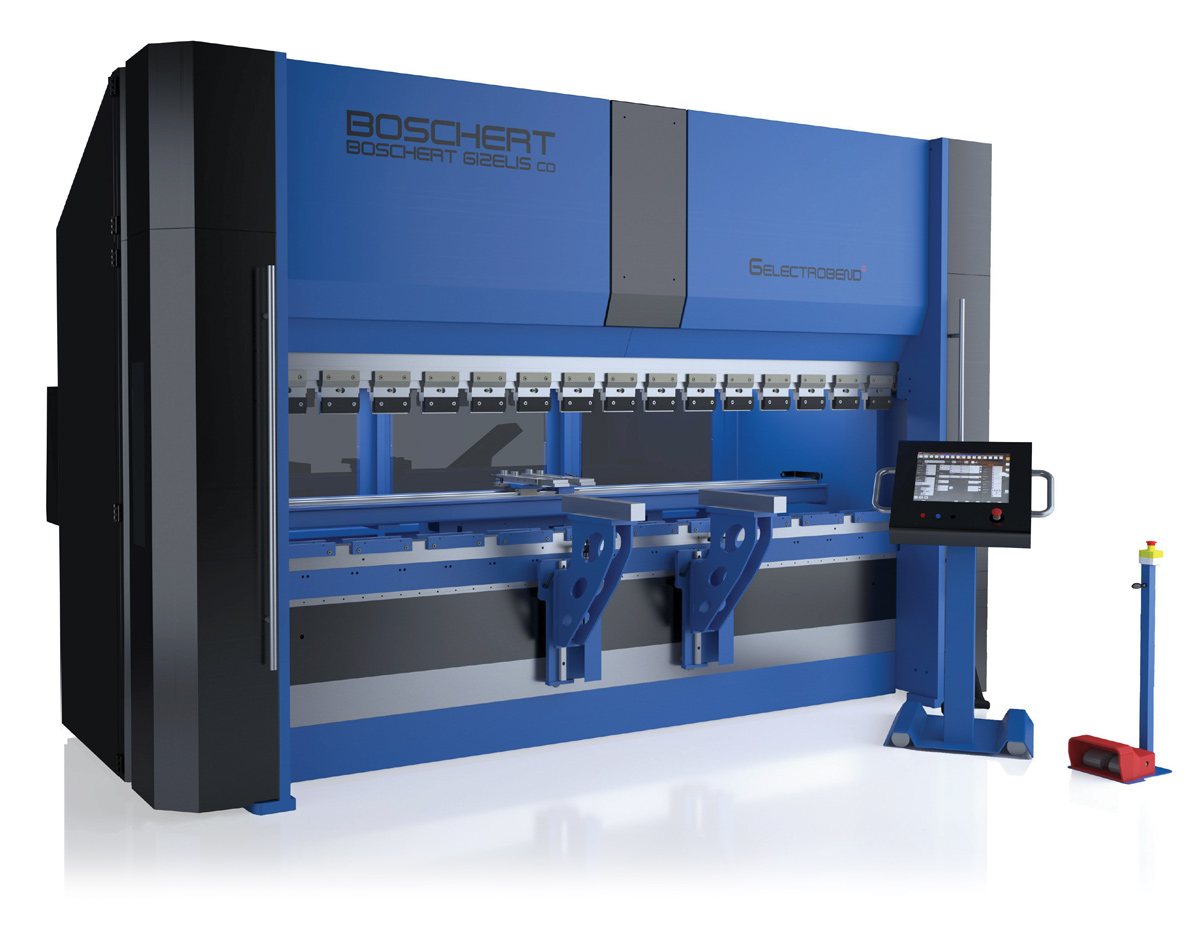

eclining costs and versatile new technologies in hardware and software are making it easier for more job shops and manufacturers to embrace IoT and IIoT—even those with legacy equipment. Boschert USA took a different approach when it introduced a new line of servo-electric press brakes in late 2019.

“When you look at a press brake, what are the issues?” says Boschert USA President Greg Hoesly. The Butler, Wisconsin-based company is the exclusive North American importer for Boschert-Gizelis as well as Boschert GmbH of Germany and other European builders with products that include profile benders, horizontal ram benders and sheet metal fabrication tools.

www.consumablesmagazine.net

Diamond Ground Products Inc., Newbury Park, California, 805/498-3837, www.diamondground.com.

American Torch Tip Co., Bradenton, Florida, 800/342-8477, www.americantorchtip.com.

Gemtex Abrasives, Toronto, 800/387-5100, www.gemtexabrasives.com.

n our family, there was no clear line between religion and fly fishing.” Author Norman Maclean penned the words in his autobiography, “A River Runs Through It.” The book chronicles Maclean’s life on the Blackfoot River in early 20th century Montana.

For Steve Bieszczat, chief marketing officer for DELMIAWORKS (IQMS ERP), there is no clear line between ERP software and manufacturing but rather a “continuation of trends.” Headquartered in Paso Robles, California, DELMIAWORKS develops enterprise resource planning (ERP) and manufacturing execution system (MES) software for discrete and batch process production spaces. The software supplier has collected feedback from countless customers to make ongoing improvements to its products. “In a way, our system represents the combined wisdom of thousands of successful manufacturers,” Bieszczat says.

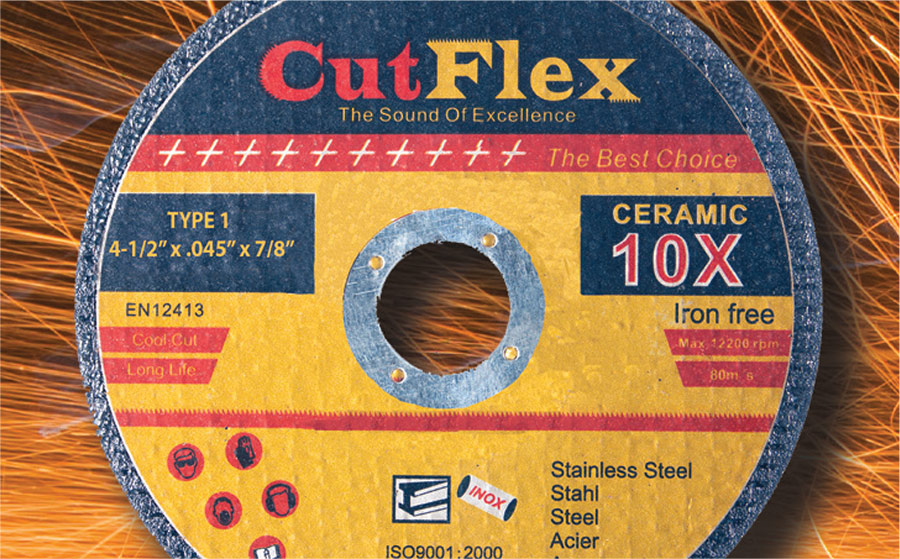

f you work with a cutoff wheel or grind wheel, you know firsthand that changeovers can be time consuming. In a high volume environment, that time lost to changing attachments adds up quickly. The latest in Bosch technology has simplified grinder attachments resulting in a simple on-and-off snap. It’s five times faster to change out attachments with no need for extra tools. When used with Osborn X-Lock tools, the attachments are safe and backward compatible with conventional grinders.

ompanies merge, and with that connection, change follows—in leadership, facilities and day-to-day operations. After Nucor Tubular Products (NTP) Group brought together the former Independence Tube, Southland Tube and Republic Conduit, the company assured its newfound customer base that it would provide expected reliability to existing as well as new customers.

NTP quelled the concerns of one of its customers, a Southeastern service center that sells $700 million worth of steel products per year. Consistency and open communication, including working with the same sales rep for more than a decade, has proven to this customer that NTP can navigate change. The service center sells wide-flange beams, plate and piling, merchant bars, pipe and tube to its network of North American customers.

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.