Features

/customfabricator

/plasma

/airfiltration

#welding #fabrication #tigwelding #metalfab #stainlesssteel

Learn more

@RogReview

From the Editor

Lessons Learned

harles Kettering said that “99 percent of success is built on failure.” The Loudonville, Ohio, engineer considered failure a close friend and an important teacher. Kettering’s “failures” led him to invent the electric self-starter for the automobile. He helped to develop the first cash register and was instrumental in developing quick-drying automobile paints and finishes, the variable-speed transmission and the refrigerant Freon.

As an Ohio native, I’m a little biased when it comes to the Buckeye state’s long history of individuals who pioneered technology that changed the way people lived. Not far from where I live, Orville and Wilbur Wright made history at Huffman Prairie when they achieved the first sustained flight. Thomas Edison, another Ohioan, invented the first vacuum bulb with metal filaments for practical lighting, the movie camera and the first alkaline storage battery. Granville Woods, self-taught, worked his way up in the rail industry and is credited with 35 patents for electrical and mechanical devices that made significant improvements to the railroad system. Neil Armstrong, born in Wapakoneta, Ohio, was the first man to walk on the moon.

Industry News

n his 1948 speech to the House of Commons, British Prime Minister Winston Churchill said, “Those that fail to learn from history are doomed to repeat it.” More than 70 years later, the iconic phrase raises an important question for service centers and manufacturers impacted by supply chain shortages. The black swan event that stretched around the world has exposed the frailty of the system, leaving U.S. businesses scrambling to gain a foothold in a volatile economy. Chicago Tube & Iron Co. Chairman Dr. Donald McNeeley, Ken Kaufmann Jr., president of CEP Technologies Inc., and Scott Schrinner, head engineer for a large HVAC manufacturer, talk frankly about the pitfalls and some of the steps they have taken to navigate the day-to-day challenges.

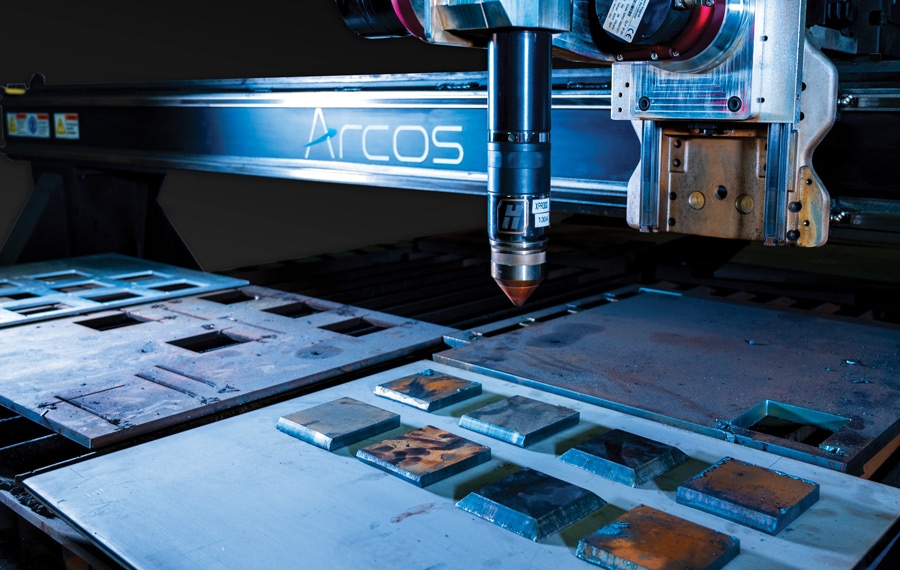

MC Machinery’s Mitsubishi 10,000-watt GX-F Advanced artificial intelligence-enabled fiber laser uses less gas and energy while shouldering the work of four CO2 lasers

e are not a conventional fabrication shop,” says Cody Waggoner, president of Lasernut. “We do a lot of out-of-the box thinking.” The cutting specialist is a division of Industrial Process Equipment, a company started by Waggoner’s father, Jim, in 1984. IPE makes powder coating equipment and other machinery for customers across the globe.

Cody Waggoner credits his dad with his work ethic and his interest in metal fabrication. “I’ve ‘worked’ for the company ever since I was in diapers,” he laughs. “I went to work for IPE full-time as an 18-year-old high school graduate. Even though my dad owned the company, I still had to interview with the general manager. I did everything from sweep floors and clean bathrooms to learning CAD/CAM.”

John Woolworth, left, and Alex Nolan use Boschert’s Stierli 220-ton CNC horizontal bender.

thing of beauty is a joy forever.” The familiar phrase was penned by John Keats in 1818 as the opening line to his poem “Endymion.” John Woolworth is also making things of beauty using stainless, aluminum, bronze, brass and steel. He established Pfunder Metalwerks in 2015 to design and fabricate custom products that range from lighting fixtures, table and bench legs to retail store display cases and structural parts. The company name is a nod to his family’s German heritage.

Woolworth’s eye for detail and his knack for combining function and quality with exquisite lines have boosted growth for his Sonoma, California-based business year over year. When a commercial property developer in Fairfield, California, commissioned Pfunder Metalwerks to contribute to the design/build of 14 tables and 28 benches for a new coffee shop’s interior and exterior spaces, Woolworth went shopping for a new CNC horizontal bender.

Deburring/Finishing

Fabricator uses grinding technology to make deburring process safer and more efficient

hen the late Ted Corbin founded Metal Trades Inc. in 1962, he had one piece of welding equipment and a pickup truck. Since then, the family-owned company has grown exponentially. Metal Trades earned certification as a Master Ship Repair Contractor for the U.S. Army and has an Agreement for Boat Repair with the U.S. Navy. The company developed into a multi-skilled specialist in heavy custom steel fabrication for barge/commercial marine construction and ship repair.

ESAB Welding and Cutting Products, Annapolis Junction, Maryland, 800/372-2123, esabna.com.

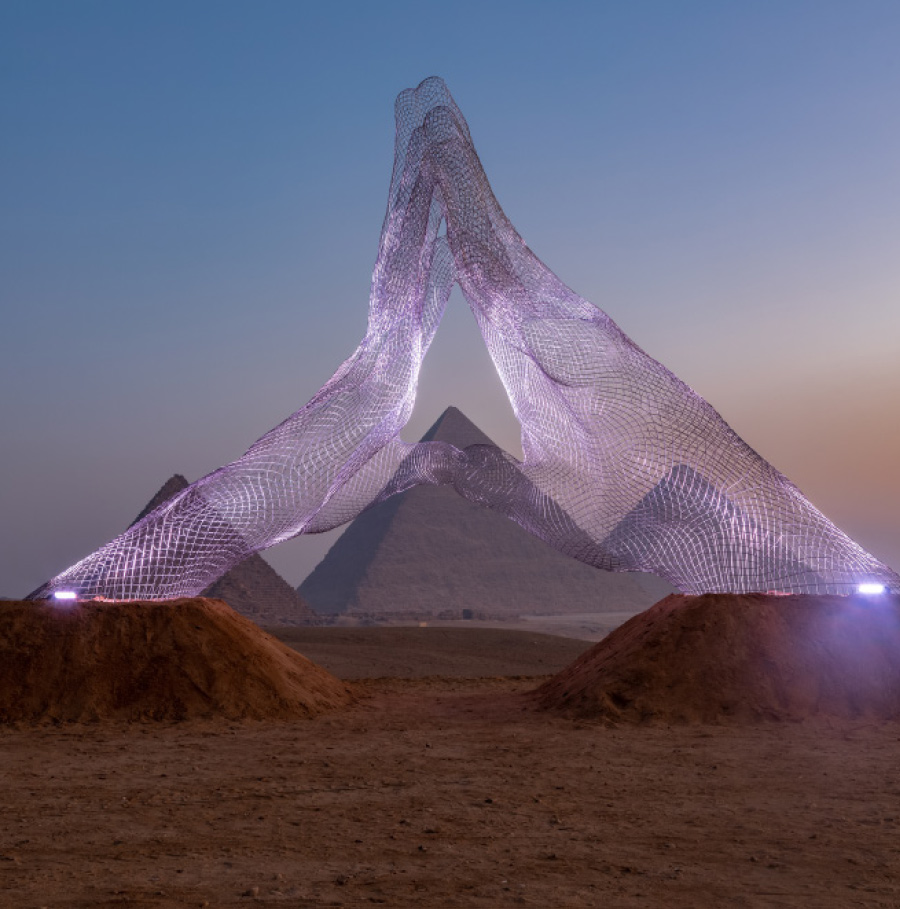

Together, created by artist Lorenzo Quinn, represents that timeless human emotional journey in a place on earth where time has become relative as a testimonial to living the moment. The sculpture is a made of 4 mm to 6 mm stainless steel wire with over 35,000 welding points. The connecting male and female hands weigh 600 kg and is part of Art D’Égypte’s fourth annual exhibition, Forever Is Now, at Cairo’s Pyramids of Giza. The first of its kind in 4,500 years, Forever Is Now is the first international art exhibition to take place at the Giza Pyramids and the surrounding Giza Plateau. “I chose to create this work for this site to honor the fact that society always works better and can surpass any obstacle when it works together,” Quinn said. “[The] sculpture outlines the human connection through time.”

Together, created by artist Lorenzo Quinn, represents that timeless human emotional journey in a place on earth where time has become relative as a testimonial to living the moment. The sculpture is a made of 4 mm to 6 mm stainless steel wire with over 35,000 welding points. The connecting male and female hands weigh 600 kg and is part of Art D’Égypte’s fourth annual exhibition, Forever Is Now, at Cairo’s Pyramids of Giza. The first of its kind in 4,500 years, Forever Is Now is the first international art exhibition to take place at the Giza Pyramids and the surrounding Giza Plateau. “I chose to create this work for this site to honor the fact that society always works better and can surpass any obstacle when it works together,” Quinn said. “[The] sculpture outlines the human connection through time.”

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

J. Neiland Pennington

Lauren Duensing

Alan Richter

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.