s a fourth grader, Brent Huey spent his days after school at his father’s job shop. Since then, he’s taken over operations at family-run Nanticoke Consulting Inc., Houston, Delaware, serving the manufacturing, aerospace, medical and equipment sectors.

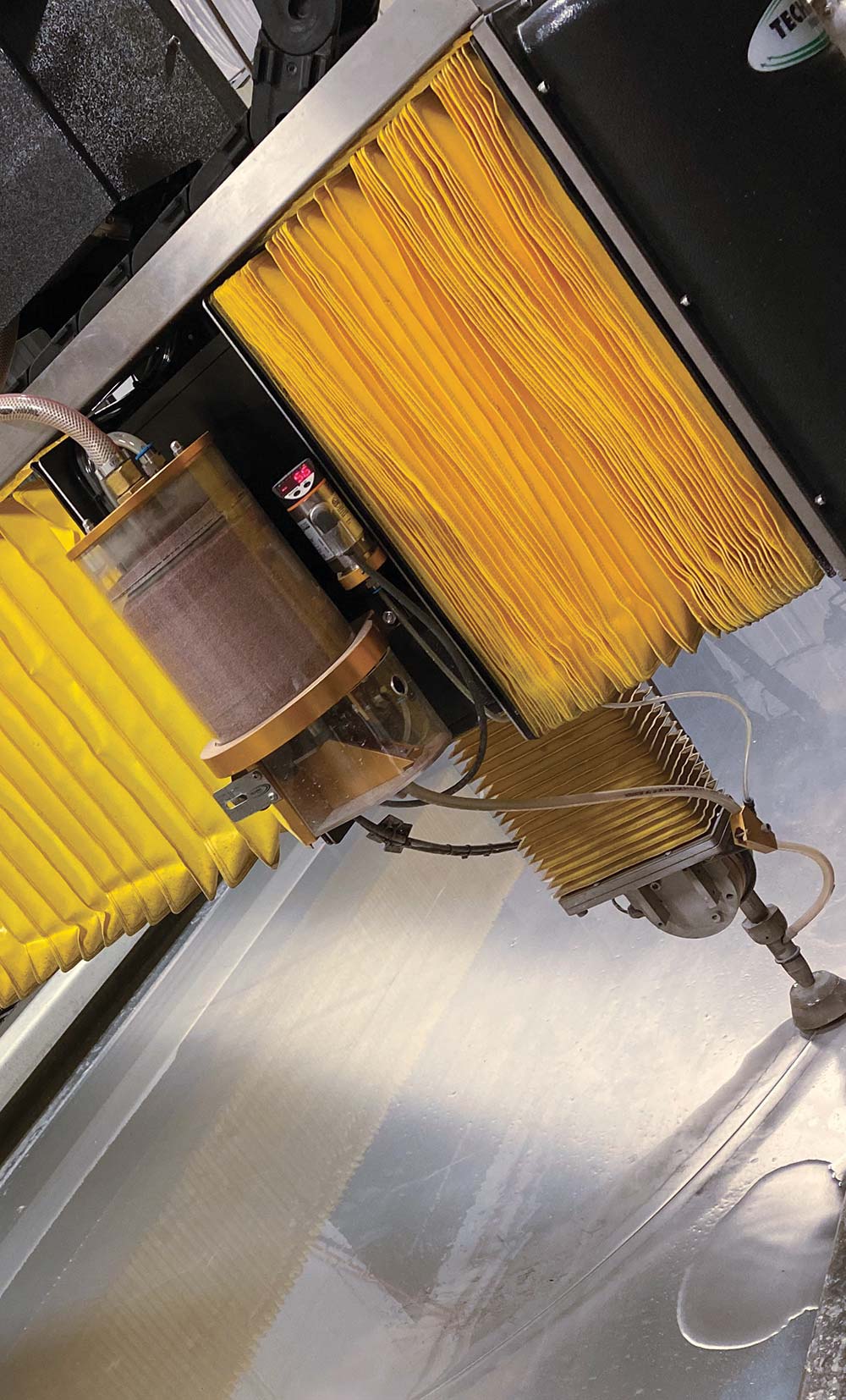

To become more versatile and cut more materials, Nanticoke invested in a TJ4000-X3 waterjet from Techni Waterjet. “We needed a [machine] that could cut everything from metal to thermo plastics to upholstery,” says Huey. “The Techni can run up to 8-in.-thick materials so being a job shop, we knew this would help us meet customer demand.”

Accuracy and consistency aside, Huey also wanted a machine that anyone could run. “I run the machine and we’re a small shop. I didn’t want to have to pay someone to stand at the saw,” he says. “I can throw sheet metal on the waterjet, set it up and let it cut until we pull the pieces off to send it to the secondary operation.”

Techni’s waterjets are ideal for different sized shops. “User-friendly software, maintenance and operational features allow customers to become quite proficient in a very short period of time,” says Jim Fields, vice president of sales and marketing at Techni. “In addition to low capital investment, Techni has been able to reduce day-to-day operational costs by over 25 percent of the market standards.”

Maintenance is minimal as the servo pump only draws down electricity and water consumption when the cutting head is cutting,” Fields says. “Our Servo technology reduces dead-head pressure spikes plus prolongs the life of high-pressure components, further lowering operating cost.”

We’re a small shop. I didn’t want to have to pay someone to stand at the saw.

We’re a small shop. I didn’t want to have to pay someone to stand at the saw.

Nanticoke Consulting Inc.

Many shops remained opened as essential businesses during these trying times. “We’ve taken advantage of a slower market and spent time internally improving Techni’s existing features and to further the intelligence of its advanced diagnostics,” Fields says. “We have simplified the operator interaction by improving the pump’s own intelligence.”

The goal is to reduce the need for human decision-making regarding maintenance and operation. New technology features should be released in early 2021.

Like so many businesses, the urge to help during this pandemic prompted Nanticoke to once again use its Techni to create intubation boxes for hospitals with the help of GoFundMe donations.

“When COVID hit NYC hard, everyone was being intubated,” Huey says. “We were able to donate 42 intubation boxes that went to New York, Florida, West Virginia as well as right here in Delaware.”

“Waterjets are a very utilitarian machine,” Fields says. “Much like the Bridgeport mill, which are in most machine and fabrication shops, the waterjet is essential in cutting metal, stone, composite or glass.”

Jobs remain lined up in queue at Nanticoke. “Adding the waterjet to our production line leaned us out. We can set it and forget it,” Huey says.