seasoned welder, artist and welding educator, Sean Flottmann volunteered at the American Welding Academy to reach out to students about a possible career in welding. “I volunteered at open houses and held demonstrations at different schools and other locations,” Flottmann says. After months of volunteering, Flottmann officially joined the American Welding Academy full-time.

Flottmann wanted to leave his day job as a full-time welder in order to work with students and gain time to work on his own welding projects. “Volunteering allowed me to segue into my role as a student outreach coordinator,” he says. “I no longer had to weld eight to 10 hours a day for a fab shop only to come home and try to fit in my own artistic welding projects well into the night. Now I am able to teach welding and not spread myself too thin.”

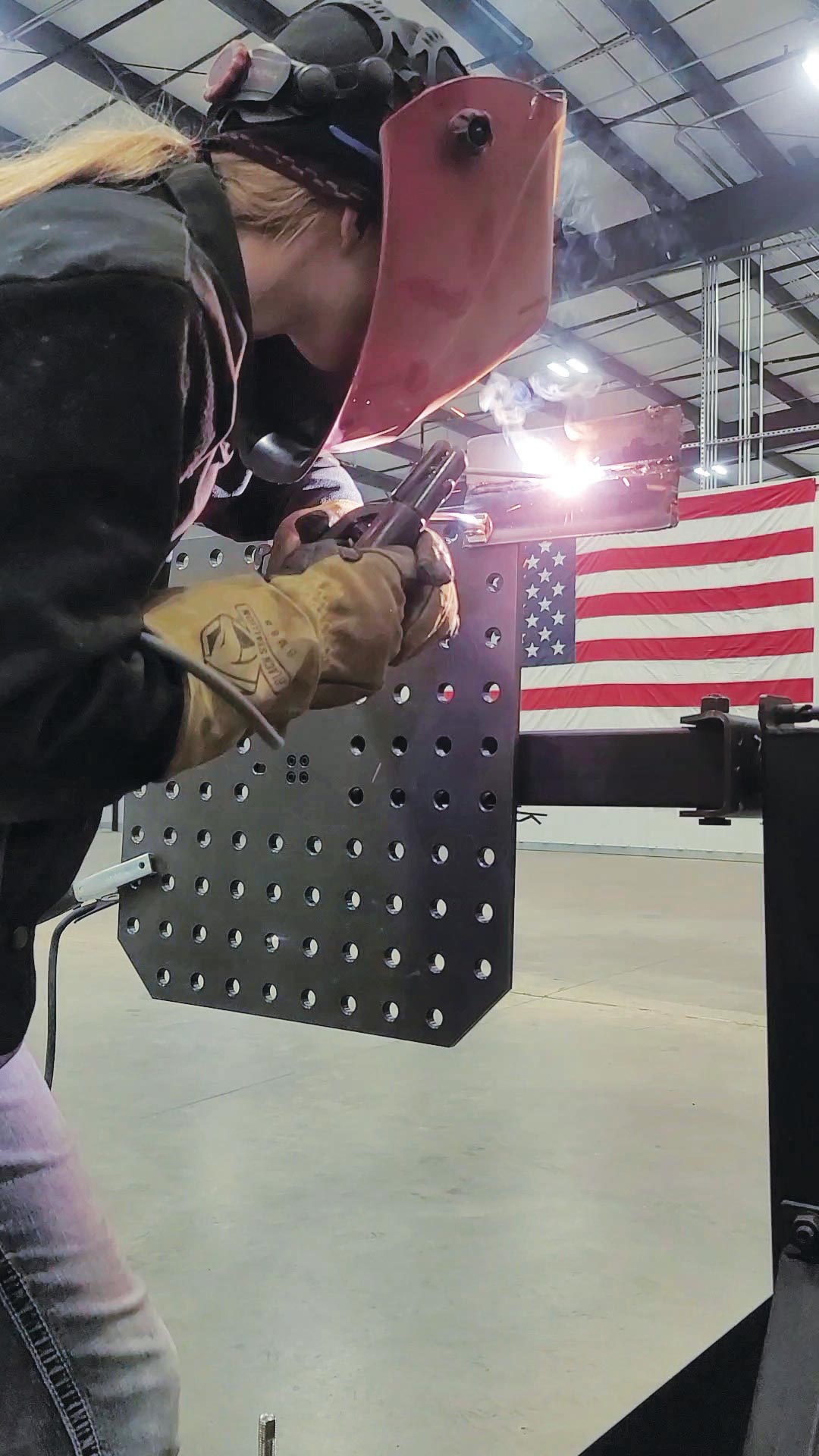

His experience includes working with various types of equipment, including welding manipulators. “I realized that the Strong Hand Tools Manipulator I used at my old job was perfectly suited for teaching,” Flottmann says. “I have a Rhino Cart (3 ft. by 4 ft.) and I am able to use the Manipulator as a standalone table or with a table I already have.

“The Manipulator’s machine holes are all the same size so it’s easy to swap out tooling between it and my table,” he continues. “The Manipulator in conjunction with my Rhino Cart can easily span the 18 ft. distance [in my shop] without all the clutter of a typical table in the way.”

The Manipulator combines an eight-sided 20-in.-by-20-in. fixturing table attached to a flexible articulating arm that locks in place at the desired position. “We mounted all this into a small rolling platform for easy mobility,” says Joel Chinchilla, marketing manager at Strong Hand Tools. “The fixturing table elements are all TM system-compatible, which means you can use any of our wide range of BuildPro clamps and fixturing components currently available.

“This combination provides a new level of control to lock a workpiece in place at any position and angle,” he continues, “providing unparalleled comfort and control.”

Welders come in all shapes and sizes, and the table is adjustable to meet each individual’s needs. “We’ve got a 17-year-old, 5-ft. 7-in. student using it for one session followed by a 275-lb., 6-ft. 7-in. student the next,” Flottmann says. “It’s nice to have the kind of flexibility as a catch-all for a wide range of students.”

Strong Hand Tools also released an updated version of Magtab HD. “Welders know heat is a terrible enemy of magnets,” Chinchilla says. “However, sometimes we can’t avoid exposing our tools to heat. We redesigned our new Magtab HD so that now all magnets are replaceable.

I realized the Strong Hand Tools Manipulator I used at my old job was perfectly suited for teaching.

I realized the Strong Hand Tools Manipulator I used at my old job was perfectly suited for teaching.

Strong Hand Tools listens to customer feedback and incorporates it into its ever-evolving designs. The company’s Rhino Cart offers users mobility while serving as a heavy-duty fixturing tabletop. “You can also use all of our BuildPro TM system clamps and components with the Rhino Cart,” Chinchilla says. “We also offer several kits such as a tube notcher and vise mount adapters that expand the cart’s capabilities and functionality.”

By learning with a Manipulator, Flottmann says students are taught lessons they will carry with them into the field. “Even if they don’t have one at their job after school, they’ve learned the value of having the right tools at hand while welding,” he says. “The right tools change everything. I personally know what it’s like to be given leftovers to use. Students can immediately see the difference between having the right tools at hand versus given tools not ideal to the setting.”

stronghandtools.com.