Toolbox

Tooling

Robotic tool changer offers configuration options

The QC-7 Robotic Tool Changer is a lightweight yet durable tool changer offering a variety of configuration options with ATI’s Pass-Through Utility Modules and Tool Stand systems. An optional ML12 Electrical Module attaches easily to the QC-7 Tool Changer body, which also includes five pass-through air ports and lock/unlock air fittings. The QC-7 Robotic Tool Changer features a low stack height and mounts directly to ISO 9409-1-31.5-4-M5 robot wrists. This tool changer is compatible with ATI’s modular Tool Stands and has an optional tool storage hook to make robot programming easy. The pneumatically actuated QC-7 features No-Touch locking technology and a patented Fail-Safe locking mechanism for a secure connection between the master and tool. The design integrates lock/unlock sensors without the need for an additional interface plate. This tool changer handles payloads up to 35 lbs. (16 kg) and is compatible with variety of industrial and collaborative robot models.

ATI Industrial Automation, Apex, North Carolina, 919/772-0115, ati-ia.com.

ABRASIVES

Fiber discs increase cut rate and life

Norton BlazeX F980 fiber discs with premium ceramic alumina micro-fracturing grain are designed for a wide range of grinding processes in stainless steel and harder-to-grind materials. New proprietary COOL FRICTION technology dissipates heat during the grind, reducing rework and extending the life of Norton BlazeX F980 fiber discs. In addition, a self-lubricating grinding aid treatment and active filler are also critical to producing cool cuts. Its micro-fracturing grain consistently exposes sharper grain edges to deliver a better cut rate and longer disc life when compared to blended ceramic alumina discs.

Saint-Gobain Abrasives, Worcester, Massachusetts, 508/795-5000, nortonabrasives.com.

HAND TOOLS

Air gun capable of tough jobs

The VariBlast Precision Safety Air Gun with Nano Super Air Nozzle provides a focused blast of air capable of handling tough jobs with remarkable strength. This CE compliant lightweight air gun employs an engineered variable flow trigger able to produce variable force upon a target simply by pulling the trigger. A comfortable full-finger trigger and convenient hanger loop are built-in to this 1/4 NPT Safety Air Gun. The Nano Super Air Nozzle requires only 8.3 SCFM and is made of Type 316SS or PEEK thermoplastic. The VariBlast Precision Safety Air Gun is available with a standard, 12 in. or 20 in. extension, which can also be outfitted with an impact-resistant polycarbonate Chip Shield.

EXAIR Corp., Cincinnati, 800/903-9247, exair.com.

EDUCATION

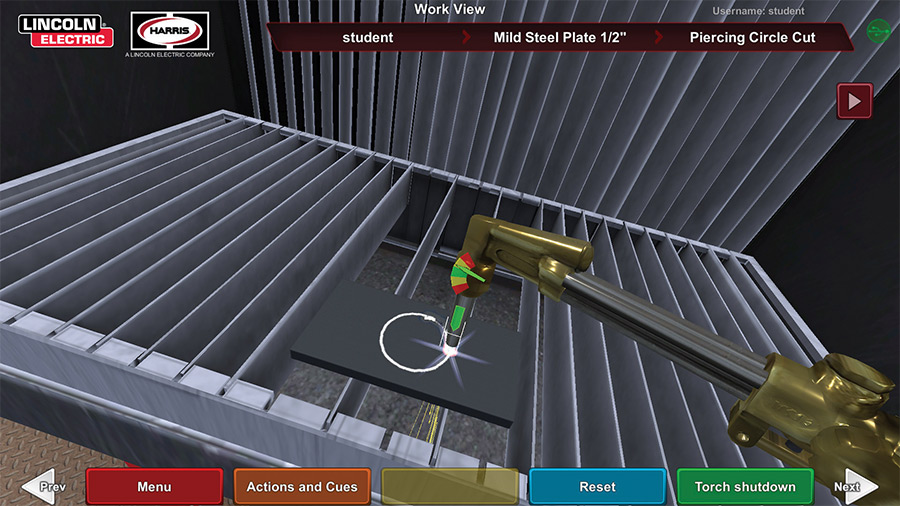

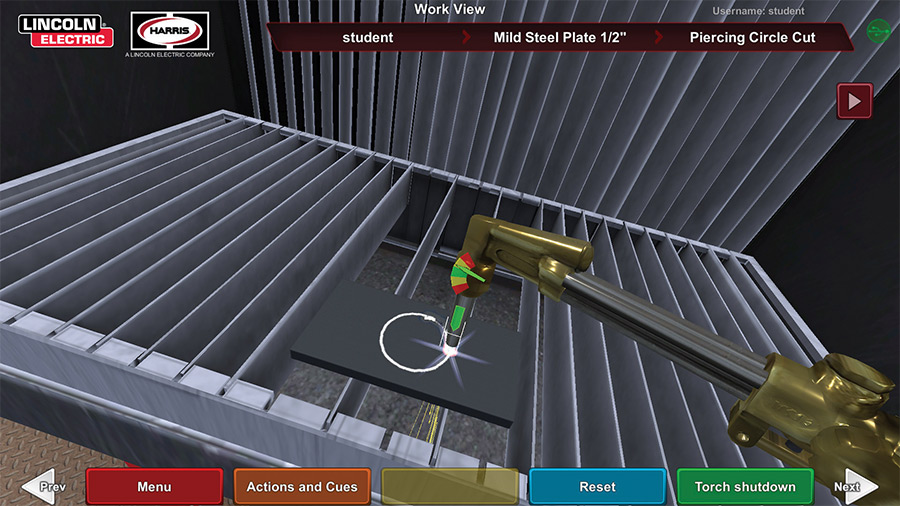

Practice torch cutting safely and virtually

The VRTEX 360 provides a best-in-class, advanced-level virtual reality welding simulation training experience for educational or industrial environments. It can be used for fundamental welding training, skill enhancement, diagnostic testing and instructor preparation. Virtual reality arc welding trainers provide a powerful, cutting-edge solution for cultivating welding talent quickly and resourcefully. Together with the MIG, stick and GTAW devices, they simulate the look, feel and action of actual guns and torches.

Lincoln Electric, Cleveland, 888/935-3877, lincolnelectric.com.

BENDING

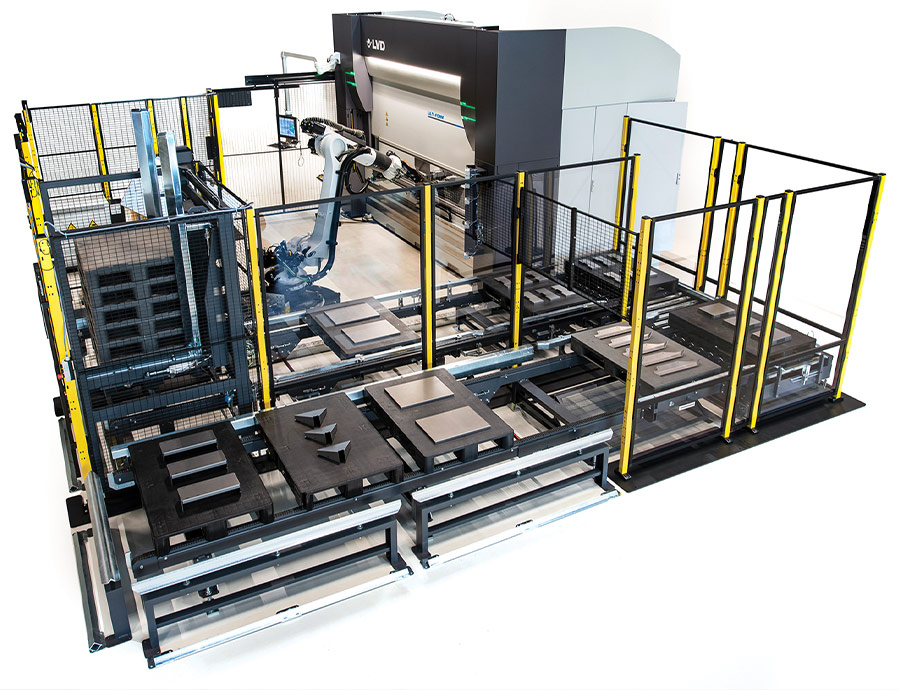

Bending system adds automated tool changing press brake

Ulti-Form is a new robotic bending system featuring an automated tool changing press brake. Ulti-Form follows the success of LVD’s Dyna-Cell robotic bending cell and takes automated bending technology a step further by incorporating an automated tool changing press brake to keep bending productivity at its peak, handling both small batches and long production runs efficiently with minimal changeover time. Ulti-Form delivers high productivity bending with unattended operation. Designed for flexibility, Ulti-Form can operate automatically or in manual mode. Manual operation can be used for very complex parts and small series; automated production is ideal for long series.

LVD Strippit, Akron, New York, 716/542-4511, lvdgroup.com.

Online

find more products on ffjournal.net