Automotive manufacturers also need to think about the availability of charging stations. Tesla has a coast-to-coast proprietary network to ease buyer anxiety. Despite the bumpy ride for the automotive metal stamping industry over the last five years, CEP Technologies President Ken Kaufmann Jr. believes the market shift from a combustion engine to an EV “fueled” by a charging station is full of opportunity. The manufacturer produces custom miniature to small progressive stampings for automotive applications that include combustion engines and smart cars.

It’s an exciting time for the automotive industry. The market has never seen a change in platform like this.

It’s an exciting time for the automotive industry. The market has never seen a change in platform like this.

Ken Kaufmann Jr.

CEP Technologies

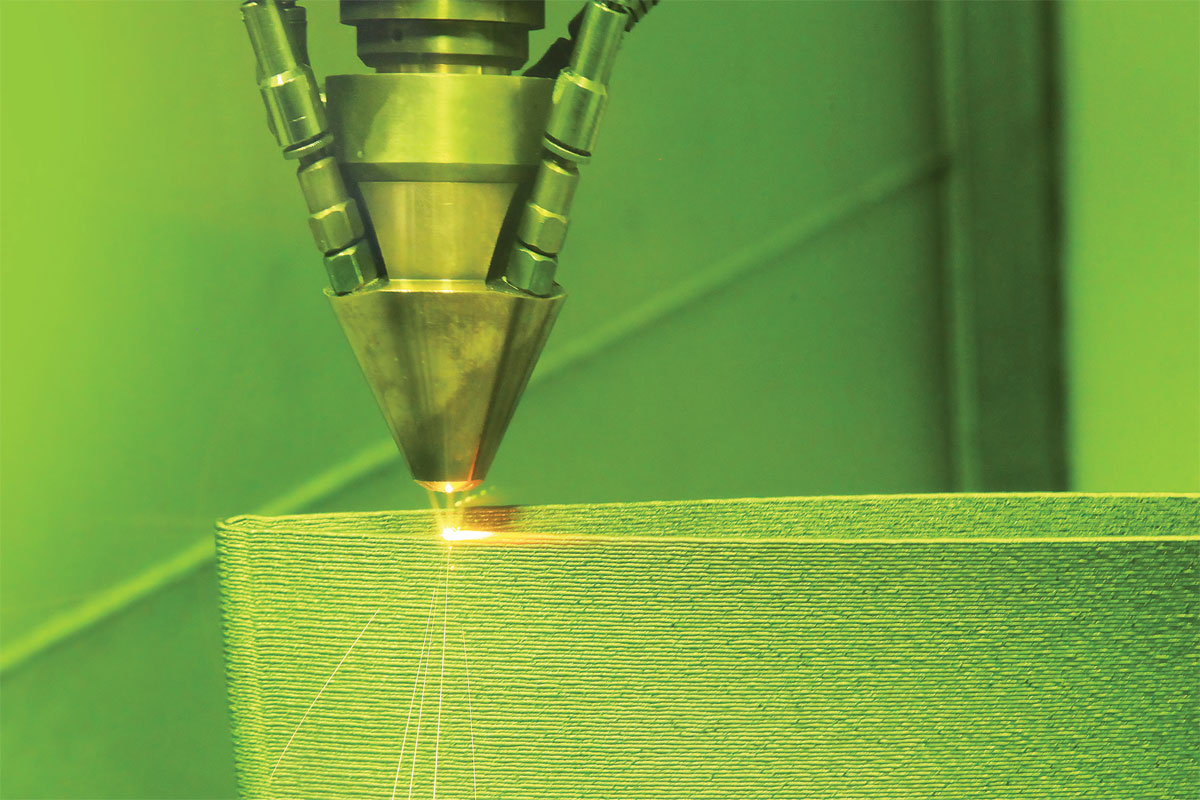

Electric terminals will likely be designed and developed in different forms and material thicknesses depending on amperage and current. There are three primary companies producing charging solutions that use bidirectional and smart charging in the form of commercial chargers, fast chargers, residential chargers and the software to run them.

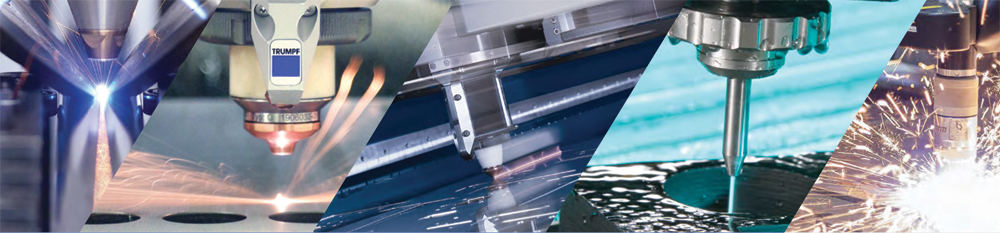

Since many of the stations will be exposed to harsh weather, demand for alloys like copper could see an uptick. Small to miniature high-precision stampings will also be needed to support electrical conductivity and connectivity.

“A stamper needs to have additional capacity and evaluate whether or not a stamped component falls within their tonnage range,” Kaufmann notes. “But there is a tremendous amount of retooling that will have to take place. Companies will need to retool and reconfigure their production lines. But that’s where the growth is and I see it as a positive for the industry.”

We ask [President Biden] to move at once to terminate the Section 232 steel and aluminum tariffs.

We ask [President Biden] to move at once to terminate the Section 232 steel and aluminum tariffs.

at ffjournal.net