steps

iewrail has built its business on eliminating installation steps for customers. That’s because the contemporary staircase and railing systems supplier predrills stair treads and prefabricates posts so no drilling, welding or assembly is required.

“Customers know exactly where each part goes at the job site with our turnkey solutions and detailed layout drawings,” says Viewrail Manufacturing Engineer Manager Tyler Garber.”

Len Morris started the Goshen, Indiana, business in 2001 with a few pieces of equipment, a code of integrity-based values and a vision. The company took off when Morris created and introduced Flight, his proprietary Floating Staircase system. Stair treads appear to float in midair without any structural support. Unlike traditional stairs, Flight staircases use a steel mono stringer that can be attached to a wall or hidden beneath the stair treads. Simple to assemble and install, the company can tailor the stringer, treads and railing to complement a customer’s surroundings.

“We’ve grown tremendously,” says Garber, noting that he was the 80th employee hired in 2018. “Today we have 300 personnel.” Morris has since differentiated the company’s product lines by creating two businesses. Viewrail features modern, elegant staircase solutions supported by advanced metalworking. Stair Supplies focuses on products that are handcrafted from wood.

steps

iewrail has built its business on eliminating installation steps for customers. That’s because the contemporary staircase and railing systems supplier predrills stair treads and prefabricates posts so no drilling, welding or assembly is required.

“Customers know exactly where each part goes at the job site with our turnkey solutions and detailed layout drawings,” says Viewrail Manufacturing Engineer Manager Tyler Garber.”

Len Morris started the Goshen, Indiana, business in 2001 with a few pieces of equipment, a code of integrity-based values and a vision. The company took off when Morris created and introduced Flight, his proprietary Floating Staircase system. Stair treads appear to float in midair without any structural support. Unlike traditional stairs, Flight staircases use a steel mono stringer that can be attached to a wall or hidden beneath the stair treads. Simple to assemble and install, the company can tailor the stringer, treads and railing to complement a customer’s surroundings.

“We’ve grown tremendously,” says Garber, noting that he was the 80th employee hired in 2018. “Today we have 300 personnel.” Morris has since differentiated the company’s product lines by creating two businesses. Viewrail features modern, elegant staircase solutions supported by advanced metalworking. Stair Supplies focuses on products that are handcrafted from wood.

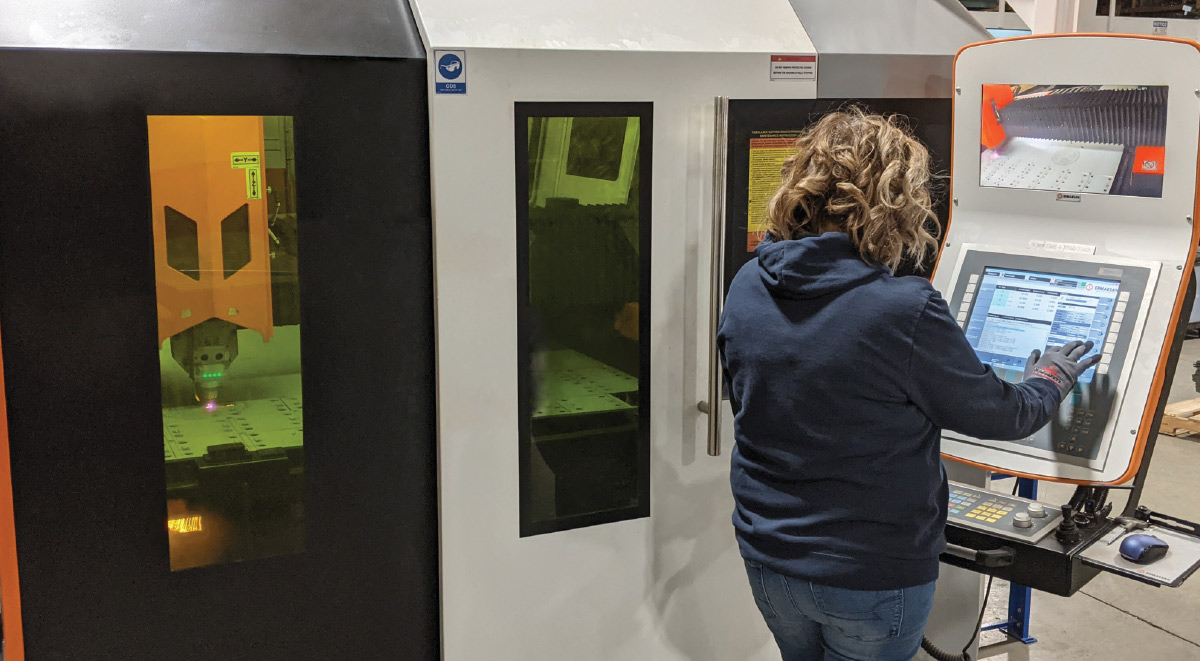

Garber was tasked to research and identify a fiber laser that could replace the CO2 lasers and provide the capacity Viewrail needed to bring parts processing back under its roof. “We looked at every brand across the board,” he says. “Bang for the buck and quality led us to settle on a Fibermak GEN-3, 6kW 3015 fiber laser.”

“Mac-Tech is based in Milwaukee, not too far from us,” Garber says. “As a family-owned business, we like to support family-owned companies. Mac-Tech was easy to work with. I have their number in my phone, and I know if I call they will provide me with anything I need right away. They have great technicians.”

Steel 5-ft.-by-10-ft. sheets are fed to the fiber laser before parts move downstream to a press brake or a machining center. “We do a lot of machining, so the parts cut by the fiber laser have to be accurate,” he says. Part quality consistency is also important because we don’t hold inventory, so we’re always cutting just the parts we need for a specific job.”

Short delivery windows mean we have to cut a variety of parts quickly.

Short delivery windows mean we have to cut a variety of parts quickly.

With the help of its research and development team, Viewrail continues to look for ways to improve its products and the service and support it provides to customers. The company is in the process of installing a fully automated powder coat line. Its ability to scale up manufacturing and prefabricate with equipment like the fiber lasers allows Viewrail to be competitive while delivering a premium product.

“Advanced machines like the Ermaksan Fibermak free up our people to spend their time finding ways to make our products stronger, better and faster,” says Garber. “It’s also nice to be able to work with one vendor to source that kind of high-end equipment.”