stronger,

faster

Stainless steel fl ights wrapped on the TAB Wrapper Tornado are ready for delivery without boxes, banding or strapping.

t is challenging to fabricate thousands of custom metal augers each year while adhering to exact specifications. Each auger must be able to withstand heavy wear-and-tear in the mining, concrete and construction industries. But the bigger problem stems from wrapping and transporting oddly shaped augers and screws for packaging and delivery.

Custom sizes and shapes require custom packaging requirements, says Steve Sogor, general manager. Since each order differs from the next, Sogor’s team of shop staffers design and build a custom pallet to fit the dimensions of the auger and carry the weight of heavy material. Sometimes these pallets reach 10 ft. long. Augers are round and smooth and therefore prone to rolling off of the pallets. Staffers have to snake metal and/or plastic banding and strapping around and under the pallet at floor level, tighten it around the product with a tensioner, and then fasten it down with a crimper. This process is repeated several times per pallet to keep augers in place. Given that a pallet load may carry upward of $5,000 of product, the safe arrival of every order is paramount.

“We were lucky that no one had a serious injury over the years, but this situation had to change,” Sogor says. “I want to make things as easy as possible for people to get their jobs done.”

Replacement chip screws for a steel plant were set on a custom-built pallet and wrapped using the TAB Wrapper Tornado.

We’re getting an extremely secure wrap now, every time, with a lot less effort.

We’re getting an extremely secure wrap now, every time, with a lot less effort.

After reviewing available options, Sogor decided on an orbital wrapper from TAB Industries. The TAB Wrapper Tornado can wrap around the product and the pallet to cover all six sides of a load. Horizontal wrapping machines can only wrap around the product itself without addressing the top and bottom of the load.

Designed and manufactured by TAB Industries, Reading, Pennsylvania, the TAB Wrapper Tornado automatically applies plastic stretch film 360 degrees around and under the pallet to create a secure, stable load that resists shifting during transit and storage. It allows heavy, round and oddly shaped products like these augers to be safely transported without banding, strapping or crates.

Since installing the patent-pending orbital wrapper, the company has not experienced a single product loss in transit. “We’re getting an extremely secure wrap now, every time, with a lot less effort,” says Sogor. “We’re getting more done much faster.”

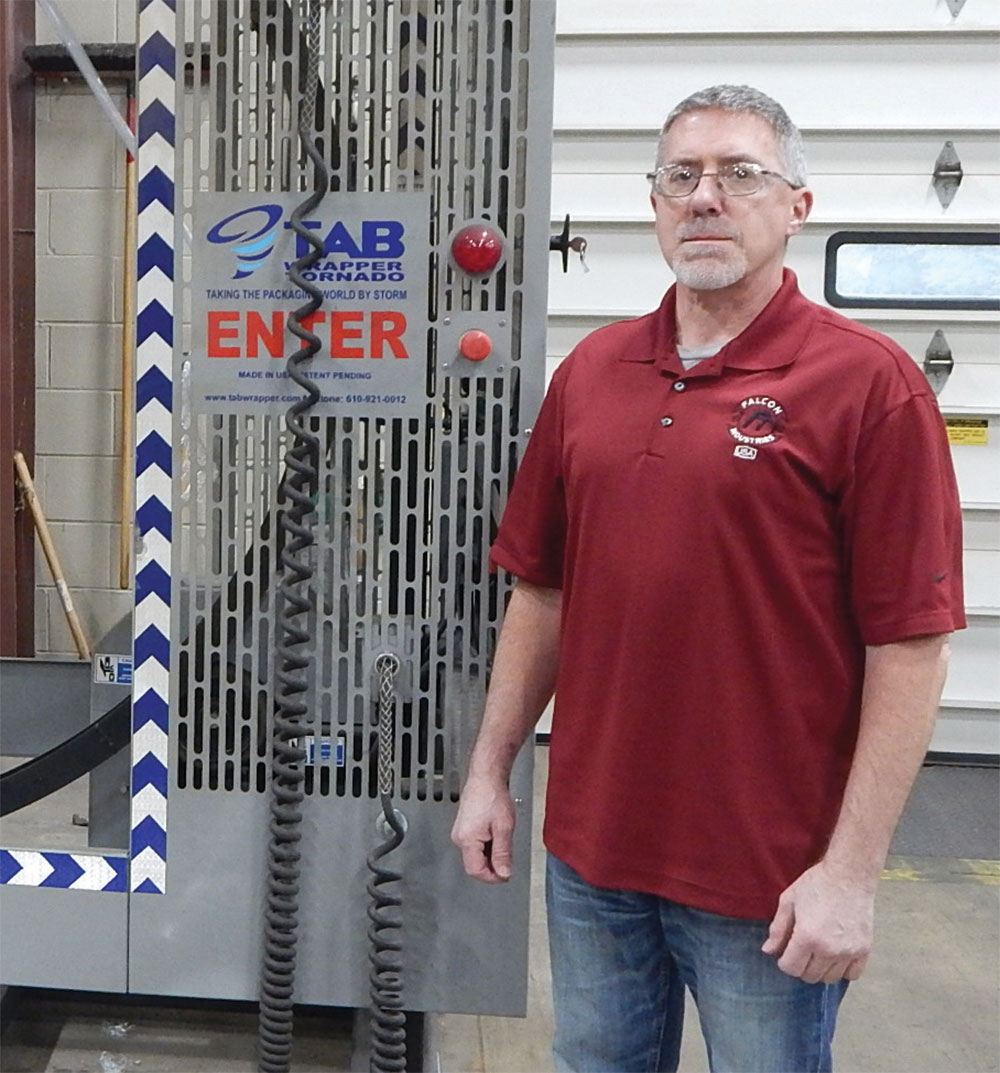

Falcon Industries General Manager Steve Sogor saved nearly 450 hours each year in the packaging department with the TAB Wrapper Tornado orbital wrapping system.

Several staffers were trained to use the machine in a matter of minutes. “Everybody is happier in the packaging department now,” says Sogor. “People touring the plant have been very impressed by the professional approach.”

The high-quality wrap also makes the augers look better on the skid. After witnessing firsthand the results of automating the wrapping process in Ohio, Falcon Industries managers purchased an identical model TAB Wrapper Tornado for its Cosmos, Minnesota, facility and anticipate comparable savings and returns.