built

ver the years, a wide range of portable equipment has been developed to perform metal cutting in-place, where it was not feasible to take the workpiece to a floor-mounted machine. For example, magnetic-based drills can accomplish drill-press accurate holes anywhere they can be attached. Similarly, portable powered threading machines quickly and easily generate excellent pipe threaded ends in the field without the need for a machine shop.

For work on tube and pipe, portable machine tools that were primarily designed for simple end preparation for welders, are being custom repurposed as dynamic and practical fabrication solutions that offer many significant advantages over conventional machine shop equipment.

Along with obvious advantages—reduced size and expense—portable machine tools are industry-proven for producing high-quality fabricated parts. They are especially effective when the production requirements for parts are of infrequent or unexpected demand, making the setup of large, dedicated shop equipment impractical or cost prohibitive.

Portable machine tools are industry-proven for producing high-quality fabricated parts.

Portable machine tools are industry-proven for producing high-quality fabricated parts.

Beveling tools typically mount to an ID bore with an expanding mandrel and produce simple or complex beveled ends, providing material clearance for the welding arc to reach the root of a weld joint profile. Beyond their basic intent, beveling tools have been custom modified to perform a wide spectrum of tasks such as high-volume grooving for non-welded pipe fittings, deep counterboring for Nondestructive Testing (NDT), and coating removal systems for working with corrosion-resistant pipe.

Severing and squaring portable machines are of particular interest to companies looking for a practical approach to tubular part fabrication without the expense and difficulty of converting large conventional shop machinery to a dedicated production role. This class of machinery was designed for precision cutting for construction and maintenance on piping systems for food and beverage plants, and hydrocarbon, semi-conductor and pharmaceutical production roles.

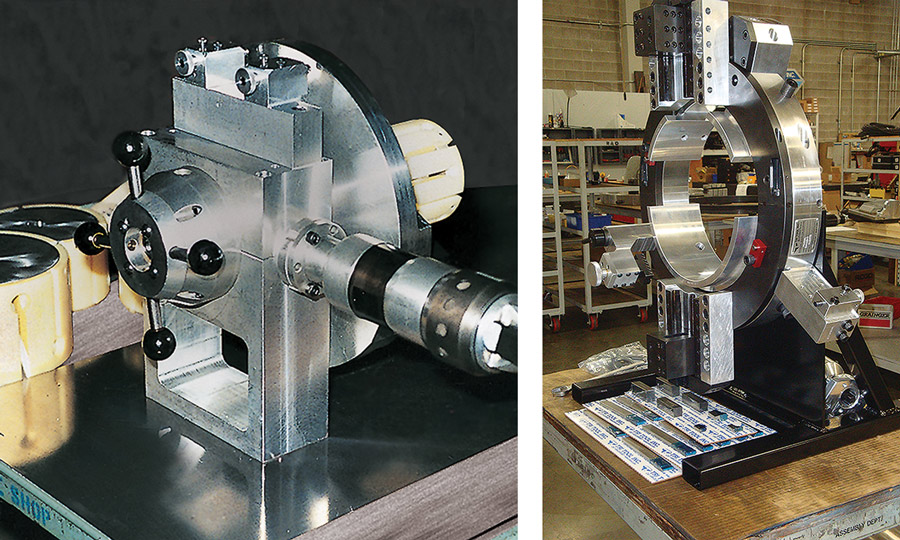

Due to the portable machine tool’s compact size, power options and the ability to bench mount or hand hold it, manufacturers have custom modified such equipment for an infinite range of applications and fabrication purposes. Cutting method options include form tool bits, standard carbide tool holders and roller cutting wheels that sever tubes without the particulate debris of saws or grinding.

Other customizable options involve methods of clamping raw stock, custom fixturing to grip the ID or OD surfaces of workpieces, and special tool bits for non-typical or complex end geometries.

The aerospace industry depends on high-integrity welded thin-wall alloy and stainless tubing assemblies. Many cutting situations require “full support” clamping elements that provide radius matched surface engagement with either the bore or outside diameter of the component being cut.

Distortion-free clamping can be accomplished by full support collets, saddle sets or contoured support pads depending on the type of machine used.

Portable machine tools used in dedicated production are very compact and flexible compared to large floor-mounted shop equipment. Fabricators gain the flexibility to set up semi-permanent workflow layouts responsive to fluctuating production demands and part inventory requirements. Machinery can be easily set up, run and then easily stored, moved or reconfigured to produce different components, in less time and in less space.

In many instances, the cutting operations achievable by custom machinery can be virtually impossible to perform with any other machinery.

In other circumstances, if an existing machine cannot be modified to perform the specific operation required, custom machinery can be designed and manufactured from the ground up, and still be cost effective if the needed fabrication can not be efficiently and/or precisely done by other means.

When using machines that rely on purpose-designed tool bits for cutting, the resultant cut geometry is a direct function of the tool bit characteristics. That’s why companies over time develop countless tool bits for specific materials, wall thicknesses, end prep profiles, as well as combination bit sets that can perform simultaneous end beveling, squaring and counterboring.

A portable machine tool manufacturer can have bit designs that number in the tens of thousands, each produced to obtain specific cutting results on a specific material. While that sounds like a daunting number, equipment manufacturers can assist fabricators with specifying exactly the right tooling to perform their required operation rapidly and reliably.

Some fabricators choose to make custom modifications that directly affect the cycle rate or the operator’s ease of use. This can include practical combinations of automated material feed, part indexing, micrometer feed mechanisms for exacting cut depth control, automated clamping and unclamping features, automated tool bit feed control to ensure repeatable precision, part ejection, and automatic resetting of the tool bit after a cut has been completed, to be ready to perform the next cut sequence.

Suffice to say, the possible fabrication options of portable machine tools are virtually limitless. Introducing a custom-modified machine tool that has been specifically built to rapidly and dependably fulfill a challenging part production requirement, can have a significant positive impact on production workflow, and save time and money.

www.tritool.com.