riter and historian James Truslow Adams coined the term American dream in his bestselling 1931 book, “Epic of America.” He described the ideal as “a land in which life should be better …for everyone, with opportunity for each according to ability or achievement.”

Today the company is a Steel Framing Industry Association (SFIA) member and has earned several Underwriters Laboratories (UL) safety certifications. The sheet metal fabrication specialist houses its operations in two buildings totaling 30,000 sq. ft. It makes and distributes steel stud and track members, radius, arch, ellipse, serpentine products, custom and heavy-gauge purlins, milling, slotted top track products with custom leg sizes, flashing, welding for wall supports, custom tube assemblies, king and jamb studs, paintable or galvanized light coves and boxes, mounting brackets and clips, milling, turning and custom fabrication. A diverse customer base stretches from construction to aerospace.

Today the company is a Steel Framing Industry Association (SFIA) member and has earned several Underwriters Laboratories (UL) safety certifications. The sheet metal fabrication specialist houses its operations in two buildings totaling 30,000 sq. ft. It makes and distributes steel stud and track members, radius, arch, ellipse, serpentine products, custom and heavy-gauge purlins, milling, slotted top track products with custom leg sizes, flashing, welding for wall supports, custom tube assemblies, king and jamb studs, paintable or galvanized light coves and boxes, mounting brackets and clips, milling, turning and custom fabrication. A diverse customer base stretches from construction to aerospace.

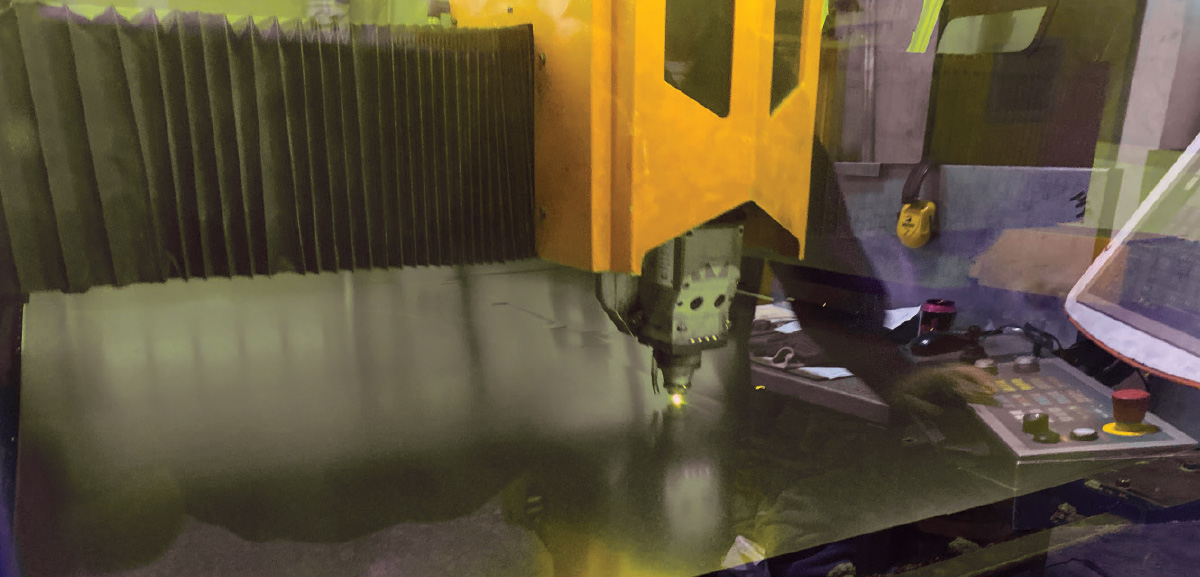

“The fiber laser allows us to optimize our manufacturing processes, and it has opened the door to new business.” The machine is able to cut carbon steel up to 5/8 in. thick, stainless up to 5/16 in. thick and aluminum up to 1/4 in. thick.

The company primarily uses galvanized steel, along with some stainless and aluminum. Baryla says familiarity guided his equipment choices. “We already had an Ermaksan press brake so we knew something about the company and their service and support philosophy. That, and the fact we got the best value for the capabilities we wanted, prompted us to invest in the Gen-3 fiber laser.”

“We were running a lot of products on older punch presses,” says Baryla. “We can make those parts on the fiber laser in a quarter of the time it took on the punch presses. We can also cut more complex shapes without having to change tooling all the time.”

For example, he says, Olmar makes parts for heavy-gauge purlins for prefabricated modular building applications. The parts are then shaped on the Ermaksan press brake. “We have a radius track part that was very labor intensive and time consuming to process on the punch press,” he continues. “We moved that job to the fiber laser and boosted throughput significantly.”

The Gen-3 fiber laser runs approximately 14 hours a day. Baryla estimates that downtime over the last four years totals a mere two days.

“Servo motors deliver 2.5G acceleration, which reduces cutting time and increases productivity by approximately 15 percent per hour,” says Senol Rodoplu, vice president of sales for Ermak USA Inc. “All Ermaksan fiber lasers are built on a single welded frame and a stress-relieved body to achieve tight tolerances.” The Lantek Expert Cut nesting software increases efficiency by providing the operator with solutions for a variety of different parts and shapes, he says. “It also calculates cut times and thicknesses for different parts, which allows companies like Olmar to estimate job costs upfront.”

“Our company was built on quick lead times, but those windows are shrinking even further,” Baryla notes. “We get a lot of makeup orders, which occur when something has been missed. If a company can’t get those parts quickly, it could mean a lot of guys standing around on a construction site waiting. We’re able to process and deliver parts quickly,” aided by a fleet of six trucks.

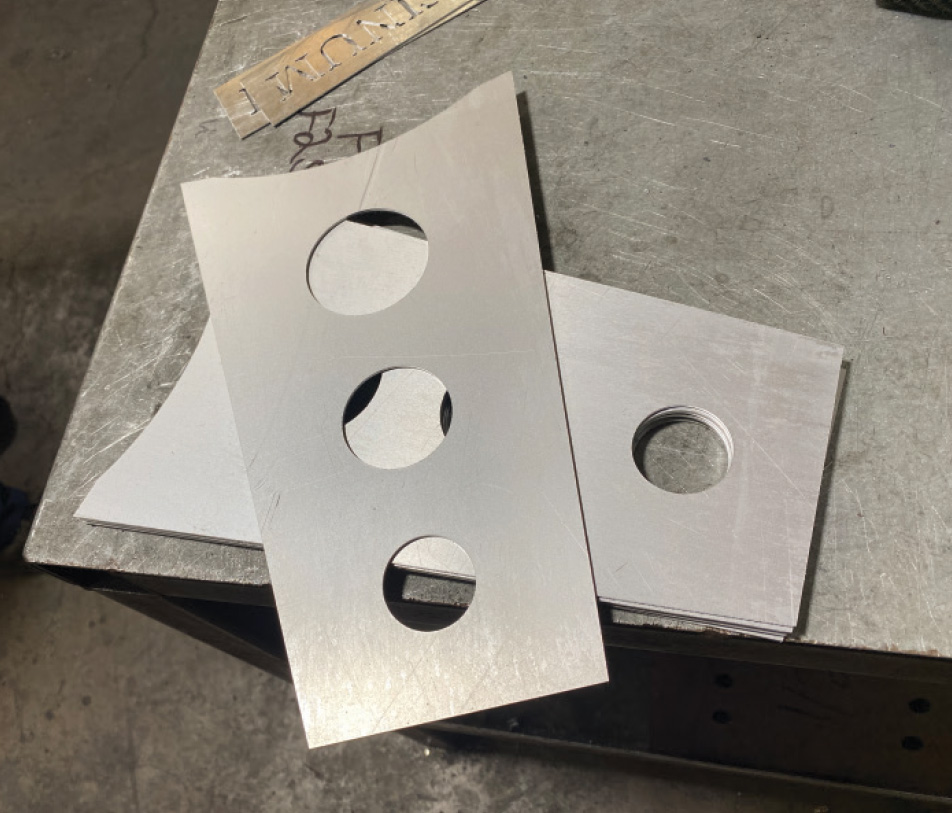

The fiber laser also handles the manufacturer’s mix of high- and low-volume jobs. A recent contract calls for the fabricator to cut 1/4-in.-thick aluminum mounts with slots and holes before the parts are sent to the press brake. “We couldn’t have done that before,” Baryla says.

The fiber laser allows us to optimize our manufacturing processes, and it has opened the door to new business.

The fiber laser allows us to optimize our manufacturing processes, and it has opened the door to new business.

“We’ve been cutting parts for a local manufacturer that makes parts for vintage muscle cars,” he says. “Those parts have to be precise because they are being welded into big assemblies. We’ve also been processing 1/4-in. and 3/8-in. stainless brackets that semiconductor companies need to bolt high-dollar equipment to the floor. It’s a high mix volume job. That’s what is so nice about the fiber laser—we can nest parts and optimize material usage.”

Baryla took charge of the company full time in 2018. “My dad said he wanted to retire so I sold my businesses and stepped in,” he says. Preserving a legacy is also part of the American dream, something Baryla is committed to maintaining for both his family and for Olmar’s customers.

www.ermakusa.com.

www.olmarsupply.com.