n his first letter to the Corinthians, the Apostle Paul said, “I discipline my body and make it my slave.”

Bisi was 14 years old when he was diagnosed with Duchenne muscular dystrophy (DMD). The rare genetic disease prevents the production of dystrophin, a protein the body’s muscles need to function properly. The chronic condition is irreversible and progressive.

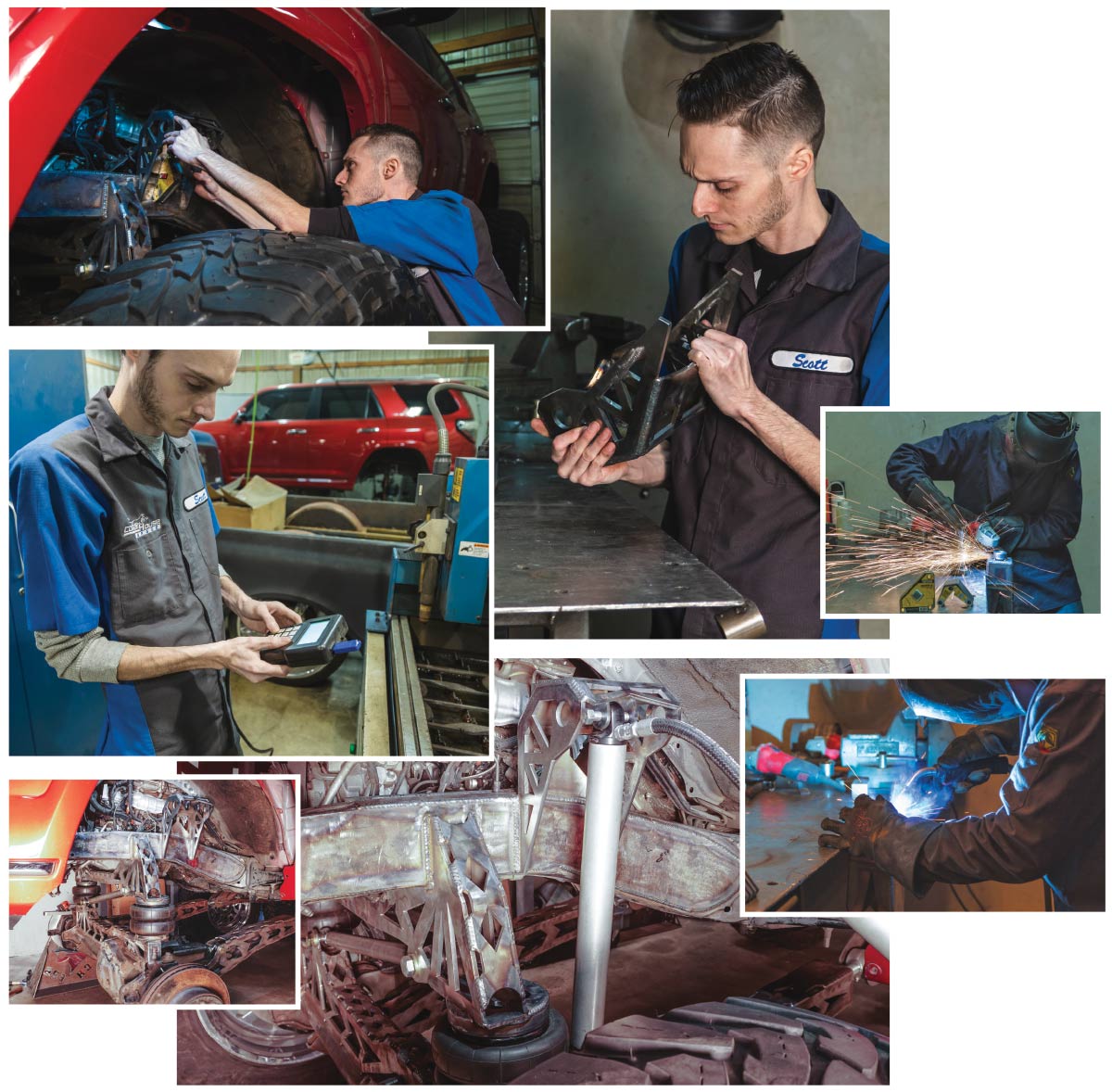

As tough as the metal he fabricates, the 32-year-old continues to defy the odds. “Being disabled is not in my personality,” he says. “That’s not my way.”

If you want to change the attitude of a vehicle, you have to change the altitude.

scott bisi,

cougar house garage

If you want to change the attitude of a vehicle, you have to change the altitude.

scott bisi,

cougar house garage

n his first letter to the Corinthians, the Apostle Paul said, “I discipline my body and make it my slave.”

Bisi was 14 years old when he was diagnosed with Duchenne muscular dystrophy (DMD). The rare genetic disease prevents the production of dystrophin, a protein the body’s muscles need to function properly. The chronic condition is irreversible and progressive.

As tough as the metal he fabricates, the 32-year-old continues to defy the odds. “Being disabled is not in my personality,” he says. “That’s not my way.”

In 2012, Bisi opened Cougar House Garage on property purchased by his mother, Jami. In addition to a house and barn, the real estate included a garage that Bisi turned into a 40-ft. by 60-ft., three-bay auto shop. He continued to hone his skills with work on custom solid-axle swaps for a variety of Toyota trucks and 4Runners. He also took on a personal project that he calls Sacrilege.

“I stripped a 2010 Ford F-350 Super-Duty truck down to its frame, added a Chevrolet independent front suspension, a Cummins 5.9 liter, 24-valve engine from a 1998 Dodge truck and 24-in. Alcoa aluminum wheels from a semitruck.” A work in progress, Sacrilege is a testament to Bisi’s fabrication expertise and sense of humor.

A frequent contributor to online technical forums, Bisi decided to chronicle the vehicle’s transformation on YouTube at the suggestion of his IT technician, Levi Woods.

“What I like about YouTube is the ability to share with others what we do at Cougar House Garage and how someone can change their own truck if they want to install a 4-link lift kit.”

In layman’s terms, a 4-link lift system uses two links per side of the axle, typically one on top and one on the bottom. Each link has one mounting point on the axle and one mounting point on the chassis. Greater suspension travel improves traction during off-road driving but also delivers better handling and a softer ride anywhere.

“I was inspired by the sheet metal art and wanted to translate that style to a mid-size 4X4,” Bisi continues. “My research showed it had never been done on a fifth-generation 4Runner.”

Bisi sought to push the envelope and build on his suspension experience but he needed the right equipment. In January 2016, Bisi installed a PT-44M CNC plasma cutter from Baileigh Industrial Holdings LLC with a 60-amp nozzle and automatic height control water table.

Technology like the CNC plasma cutter allows me to keep working.

He named the 4Runner Carnage after a Marvel Comics super villain that first appeared in The Amazing Spider-Man No. 359. “I thought it was a great name to describe such a unique, aggressive, strong-looking 4Runner,” says Bisi. “It looks like an alien.”

Bisi can custom fabricate 3-link and 4-link kits for just about any passenger vehicle made in the U.S., including Toyota and Nissan. He also ships his 4-link kits to other shops and do-it-yourselfers—raw or powder coated—for Ford, Dodge and Chevrolet vehicles.

A full-service suspension shop, Cougar House Garage also lowers trucks using air ride suspension on airbags controlled with an air management system produced by Accuair.

“Their product controls the level, height selection and how you operate the airbags,” says Bisi. “We can lift or lower vehicles from basic to extreme builds.” The plasma cutter anchors these operations and gives him control over parts production.

We can lift or lower vehicles from basic to extreme builds.

Baileigh’s software package allows Bisi to engineer parts for his kits and custom jobs.

“I use 2D design, draw up the geometry and then make cardboard stencils,” he says. “I’ll do a test run using 3/16-in. plate to make sure the parts fit and look the way I want them to. It takes more time but it’s more precise.” Bisi’s lift system allows him to drop his vehicles down for easy access.

“Scott has mastered Baileigh’s software to the point that others call him for help with troubleshooting issues they are experiencing,” says Shane Henderson, social media marketing manager for Baileigh.

Once Bisi verifies his design, his welder or fabricator will load the plasma cutter with ¼-in., thick, 4- ft. by 4-ft. hot-rolled, pickled and oiled steel sheet. “I plug in a thumb drive with my design and start cutting parts,” he says. Components are then MIG welded and assembled for a second test fit. “Once the test fit is done, we remove the parts, including frame, axles, brake calipers and discs, and send them out to be powder coated.”

When asked about his singular fascination with suspension systems, he says, “It’s what I’ve always been interested in. If you want to change the attitude of a vehicle, you have to change the altitude.” And despite his health challenges, Bisi continues to change his own altitude. “I may not be able to do things by hand anymore, but technology like the CNC plasma cutter allows me to keep working.”

Even his daily ride is modified. “I drive a Ford Super-Duty with an 8-in. lift and 38 Nitto Mud Grappler tires,” he says. “I don’t do normal.”

“I’d like to upgrade to a Baileigh 4X8 plasma cutter so I can process longer parts,” he says. “We plan to get a small forklift to load larger plate. I’m looking to acquire a TIG welder so we can work with aluminum and exotics [alloys]. I’d also like to add a press brake, lathe and powder coating booth.”

A part-time staff and a network of sponsors are critical components that help keep Cougar House Garage running but Bisi credits his family with the life lessons he has learned.

“I handle all the fabrication but my mom is my office manager,” he says. “I’m very thankful for her support and that of my sister, Kelly. My mom has always been hands on and she has taught me how to be tough.”

Jami Bisi also taught her son to appreciate the simple things, like feeding the family’s horses and spending time with his 4-year-old son Griffyn and his nephews.

“I’m in this for the long haul,” Bisi says. “I love the garage. I plan to grow old and gray doing this work and, someday, someone is going to find me with my boots on in my garage. And that will be okay with me.”