atigue is a concern for heavy manufacturing companies, especially when running through processes that require workers to move hefty material to and from multiple stations manually.

At Production Fabricators Inc. (ProFab), each part took a total of two steps on two separate machines to complete. ProFab operators would bend large batches of steel blanks, first by pre-bending each blank on a press brake. The blanks were then formed again by inserting the pre-bent ends one at a time into a manual three-roll plate roll to complete the shaping process.

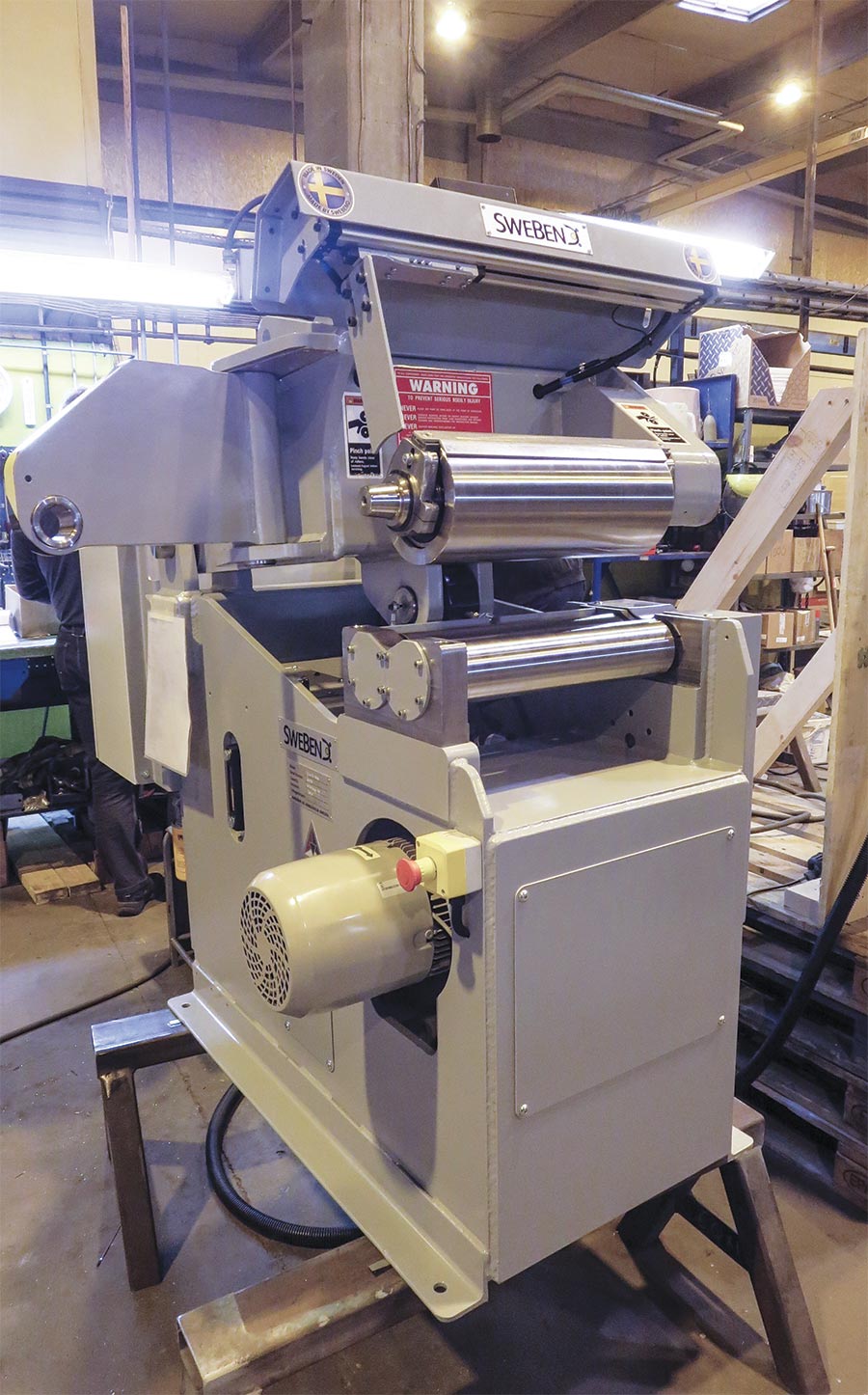

Using a SweBend QFV-1 vertical quick roll that was sourced through Trilogy Machinery (SweBend’s North American distributor), ProFab automated its bending process.

The SweBend machines [means] our operators no longer need to load and off-load manually.

The SweBend machines [means] our operators no longer need to load and off-load manually.

Winning a high-volume project is what compelled ProFab to invest in the SweBend. “Previously, we were running 20,000 parts per year at 20 pieces an hour, or 1,000 hours,” Hoofman says. “Compare that with the new roller—we run that same job producing 200 parts per hour so instead of 1,000, it takes 100 hours. That is an unbelievable productivity increase, throughput and turnaround. It clinched the work for us with that customer.”

“ProFab’s machine is run by a simple PLC but we have sold machines with full CNC capabilities to integrate with an automated production line,” says Matt Weeks, national accounts manager at Trilogy Machinery. “The SweBend quick roll series can be a good fit for a wide range of applications and create a massive ROI for a single machine to accurately and efficiently make parts that are often bottlenecks in the production process.”

“We can design and implement new or special features to suit specific needs,” Weeks says. “Features and options that benefit one customer may not benefit the next, so each project gets personal attention.”

Operator fatigue played a significant role in ProFab’s decision to invest in the SweBend. “We had one guy rolling these rings, hundreds per week,” Hoofman says. “These large rings are not easy to manually roll. He got it done but you could tell it physically wore on him. The SweBend machine was a godsend to our operators. They no longer need to load and off-load and that has helped tremendously.”

Increased capacity allows ProFab to quote additional work it would not have had time for previously. “We can run through those high-volume jobs and when those are done, our operator can move on to other tasks,” Hoofman says.

ProFab was able to recuperate its capital investment in just over a year. After six years of continuously rolling parts for the trucking industry, the future looks bright. “We don’t see demand in that industry declining anytime soon. We’re keeping busy,” he adds.