Salvagnini’s original panel bender brought flexibility and automation to the bending process using a single bending tool, a pair of counterblades, a sheet manipulator and a mechanical programmer to orchestrate sheet and bending movements. Today, Salvagnini’s panel bender has a 44-year history of innovation and improvement. The line has expanded to include three models. New features developed over the last 10 years have equipped the panel bender with significant advances in efficiency and versatility.

We can integrate any level of automation.

We can integrate any level of automation.

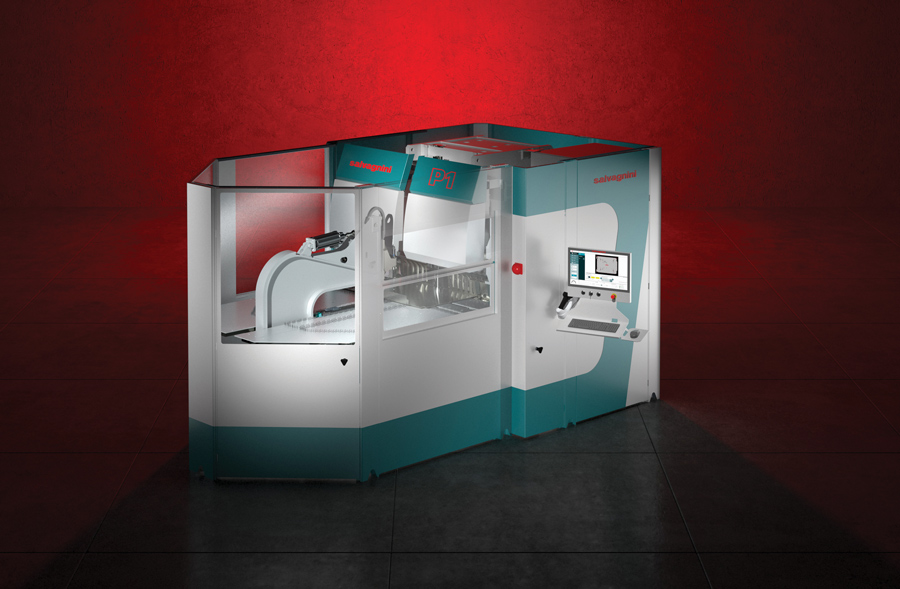

Conventional bending is characterized by an average OEE of 30 percent. Flexibility depends on the tool change system, which is often costly and time-consuming when compared to the installation of multiple press brakes or one panel bender. Salvagnini’s P1 compact electric panel bender combines productivity with automatic bending and handling cycles and universal bending tools.

The P2 provides automatic bending and handling cycles with universal bending tools. Equipped with an automatic blankholder, the P2 doesn’t require retooling and completes an average of 17 bends per minute.

The P4 lean panel bender is engineered with an automatic bending and handling cycle. Process flexibility is inherent due to universal bending tools that automatically adapt to the panel geometry in cycle, without machine downtime or manual retooling.

“For smart factory applications, we continue to develop the software side of our panel bending technology,” says Peter Kitzler, project manager for sales and application engineering. “With automation solutions like ABA, CLA/SIM, CAD/CAM stream programming, Links and Mac 3.0, our panel benders can be integrated with industrial artificial intelligence. We’ve established our SPC method [system performance control] and are currently working to provide SPP [system performance prediction] for a worry-free production environment.”

To determine if panel bending is the right choice, there are several questions a job shop or manufacturer should consider. Knowing what bend height, length, capacity (based on a four rotation, six-bend steel panel), material type and thickness cover the majority of a shop’s production volume is key. Does the operation produce narrow profiles at a substantial volume? Do the sheet metal parts to be produced feature embossing, thread forms or lances?

[Below] The P2 features automatic bending and handling cycles that can perform an average of 17 bends per minute.

Salvagnini’s North America Campus offers tours, equipment demos and training. “We have great relationships with customers,” he continues. “We can take people on a tour through a fabrication shop where they can see the panel bender operate, talk with the people who run the machine and understand first-hand the challenges of the sheet metal environment.”

With the price of raw materials skyrocketing, the ability of the panel bender to produce a good part the first time not only eliminates scrap but also reduces the amount of material a job shop needs to order. “That’s a savings that will show up in a company’s bottom line and help them gain a faster return on investment,” Langbein says.

Labor shortfalls also make the panel bender attractive. “If you can’t find operators, it’s time for automation,” Kitzler says. “A managing director for a metals manufacturer in Northern Indiana recently told me, ‘The Salvagnini panel bender has replaced eight people that I never had.’”

A panel bender is hands-off. It takes material out of the operator’s hand and produces a finished part. Part repeatability, increased capacity, efficiency and productivity allow the panel bender to fill multiple needs for a diverse range of industries from food service and appliances to exterior building cladding, light agriculture and the swimming pool construction industry. For more resources on choosing the panel bender for your business, visit us at www.salvagnini-america.com/panel bender.